Global Sand Blasting Machines Market Size, Share, Trends, & Growth Forecast Report - Segmented By Product Type (Portable Sand Blasting Machine, Mini Sand Blasting Machine), Blasting Type (Dry and Wet), End-User (Automotive, Marine, Oil and Gas, Petrochemical, Construction), & Region - Industry Forecast From 2024 to 2032

Global Sand Blasting Machines Market Size (2024 to 2032)

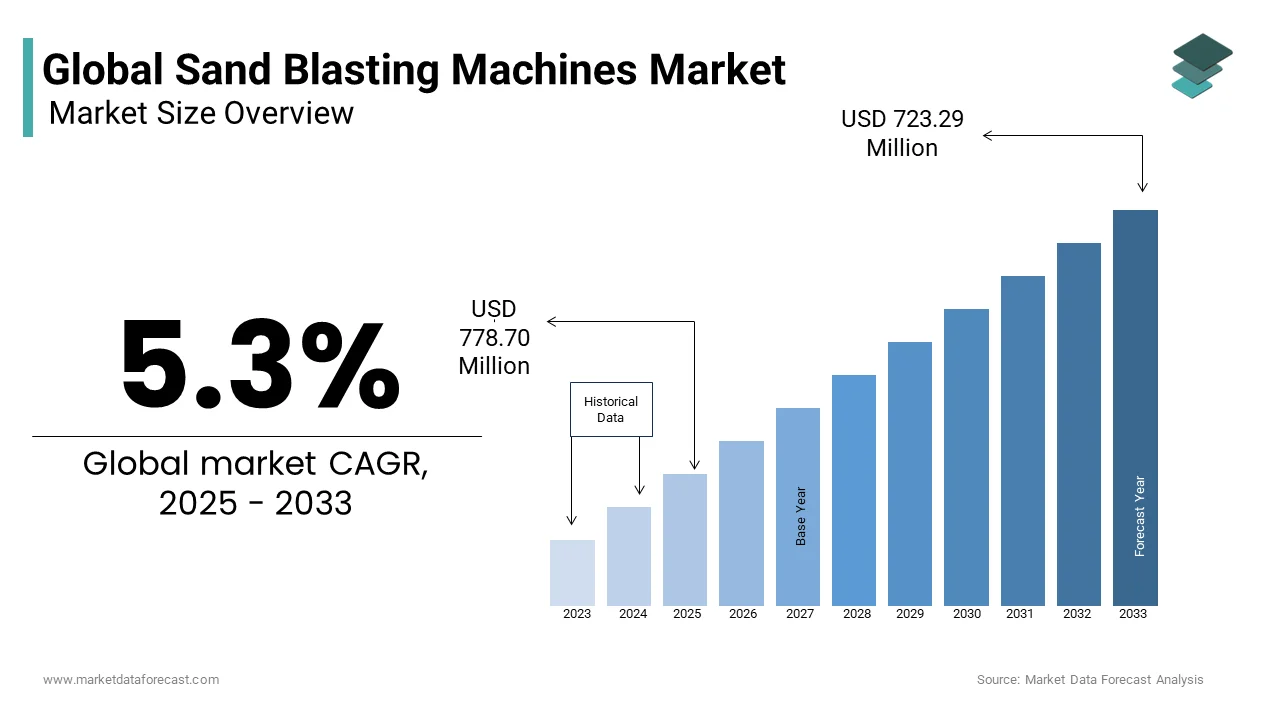

The size of the global Sandblasting Machines Market was valued at USD 431.73 million in 2023. The global market is expected to be worth USD 454.61 million in 2024 and USD 690 million by 2032, growing at a CAGR of 5.3% during the forecast period.

Current Scenario of the Global Sand Blasting Machines Market

Sand Blasting is a similar process as spraying paint on a metal surface, whereas in here the place of the paint is taken by sand and the compressed air which is used to blast around the metallic or non-metallic surfaces with maximum pressure to remove black charcoal contamination, metal oxide, and many others and it is also used to remove the rust deposit on the outer parts of metallic objects. The Sand Blasting Machine mainly relies on the Venturi Effect to suck the grit with high pressure from the tank.

With the increasing use of advanced technologies in various industries, the Sand Blasting Machines are implemented. They are adopted in domestic industrial applications in areas with high complexity. The Sand Blasting Machines will serve a high purpose in the Petrochemical and Marine Industries.

The growing usage of Automated Sand Blasting Machines in different Industries is because of the unique features of automatic data collection, automated pressure flow control, automatic recovery, and automated blast control are the shining features in Automated Sand Blasting Machines. These Sand Blasting Machines also play a crucial role in the manufacturing area of the automobile industry for smooth finishing of the surface, and these machines are also used among the local automobile manufacturers for the surface cleaning of vintage cars.

MARKET DRIVERS

In the forecast period, the demand for Sand Blasting Machines will increase in the Construction, Marine, Petrochemical, and other industries.

The main Market driving factor for Sand Blasting Machines is the technological advancement in every work sector. Moreover, the rise in demand for Automated Sand Blasting Machines because of their usage and the advantage has driven the market forward. The high usage of Automated Sand Blasting Machines also defines the market's growth.

Ongoing improvement of metropolitan regions and development industry across various districts is expected to drive interest for sand-impacting machines. In addition, fast industrialization, development in urbanization, and solid government interest in foundation improvements are driving the extension of the development business. Further, key development organizations progressively put resources into further developed structure materials and innovation for their business and private activities.

MARKET RESTRAINTS

The replacement for the Sand Blasting Machines has been done in many industries with the Shot Blasting Machines where metallic shots and grits as abrasives are involved in minoritizing the risk of lung diseases. However, in the Sand Blasting Machines, the compressed air and the sand are released with high pressure to the surroundings, resulting in silica dust, which is risky to inhale and becomes a major setback to the market.

The advancement of the organizations is focused on the superior efficiency, unwavering quality, and cost of the products. The development in the potential end-use enterprises like construction, marine, and petrochemicals is relied upon to offer significant learning experiences for the Sandblasting Machines Market. The board's health and environmental concerns and removal issues are a few affecting factors for the development of the Sandblasting Machines Market.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

5.3% |

|

Segments Covered |

By Product, Blasting Type, End User, and Region. |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

Airblast B.V., Clemco Industries Corp., Quill Falcon., Trinity Tool Company., Standard Tools and Equipment., Burwell Technologies., Torbo Engineering Keizers, Axxiom Manufacturing ABShot Tecnics, Manus Abrasive System, and Others. |

SEGMENTAL ANALYSIS

Global Sand Blasting Machines Market By Product

Based on the product, portable sandblasting machines are anticipated to dominate the global sandblasting machine market during the forecast period.

Portable Sand Blasting Machines are rapidly increasing machines because of their versatile nature. Portable sandblasters are available in the range of 40liters-140liters for dry media end-use applications. Portable Sand Blasting machines are generally flexible and can play out a wide range of dry impacts in automobile, building, and, marine applications. On the other hand, heavy-duty sandblasting machines are pressure impact machines utilized for very good quality applications like oil and gas pipelines, car suspension, weight gear creation, and so forth. Different sandblasting procedures are performed either indoors or outdoors open-air or enclosed cabinets.

Mini Sand Blasting Machines are the next market-growing machines used in houses etc. Mini Sand Blasting machines, which are more versatile, are utilized for house errands like paint removal, rust expulsion, and fixing. The Mini Sand Blasting machines market, set in the early development stage, is considered worthwhile over the estimated time frame attributable to the expanded replacement of physical work with Sand Blasting for performing homegrown undertakings to save time.

Global Sand Blasting Machines Market By Blasting Type

Wet sandblasting is expected to become a fast-growing segment due to its expanding use in businesses like paint, manufacturing, and development. The wet impacting fragment is relied upon to show massive development in the worldwide sandblasting machines market during the figure time frame. This is ascribed to the diminished danger of being dangerous or flammable during the blasting process. In wet impacting, there is less residue made when contrasted with dry blasting during impacting, and another element that makes wet blasting better is that, due to the presence of water in the framework, the material is too wet even to consider starting at any rate which makes wet blasting better while managing such kinds of materials for blasting.

Global Sand Blasting Machine Market By End-User

As far as volume, the Construction industry will have over 25% of the shares of the general business during the foreseen period. Increasing product use in the construction and fix exercises of structures will probably expand its shares in the forecast time frame. Likewise, the automotive industry will be a key end-user because of expanding item interest in vehicle fabricating and repairing applications.

Marine applications are predicted to have a steady growth rate in the global sandblasting market due to their use, such as Seawater implies salt, which helps the corrosion cycle considerably more. Users need an amazingly rough obstruction to shield the steel from consumption because these resources are exorbitant to assemble, and it's essential to support them rapidly and get them back out on the water. Marine sandblasting readies the surface to put a covering onto an obstruction to the steel to shield it from consumption. The most effective way to get a surface prepared for covering is through rough blasting.

REGIONAL ANALYSIS

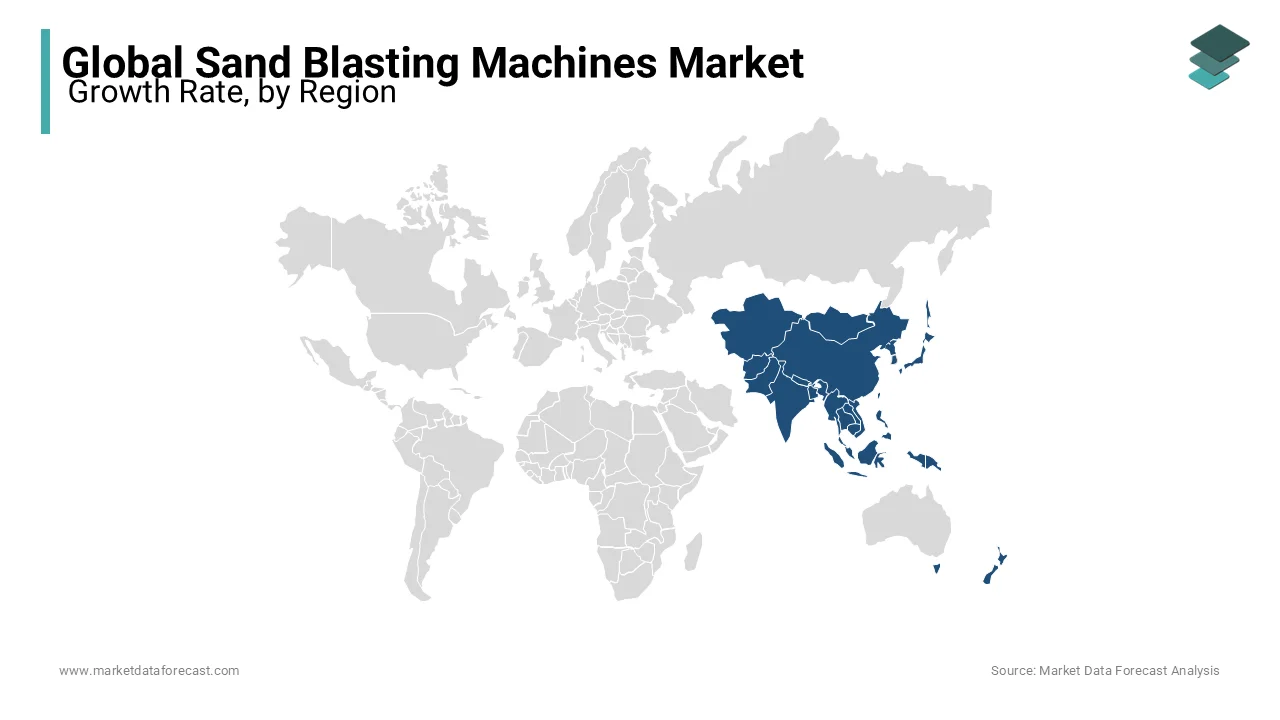

The Asia-Pacific area is relied upon to hold the main shares in the worldwide sandblasting machines market.

This is because of the expanding modern framework in nations like China and India. Fast development in construction and infrastructure alongside the expanded local automobile creation is a portion of the elements that drive the development of the sandblasting machine market during the forecast time frame.

Followed by Asia-Pacific, the North American district is likewise expected to hold a critical offer in the worldwide sandblasting machine market over the forecast time frame. Interest in portable machines is higher in the North American market, where they are utilized for home improvement just as automobile applications. Europe holds a noticeable portion of the shares overall industry as far as worth and volume.

KEY MARKET PLAYERS

Major Key Players in the Global Sand Blasting Machine Market are Airblast B.V., Clemco Industries Corp, Quill Falcon, Trinity Tool Company, Standard Tools and Equipment, Burwell Technologies, Torbo Engineering Keizers, Axxiom Manufacturing ABShot Tecnics, Manus Abrasive System, and others.

RECENT HAPPENINGS IN THE MARKET

- CLEMCO Industrial Corps has introduced the classic Blast Machines: Versatile, Reliable, and rugged One-Operator Field Portable Machines with capacities holding 1 & ½ cuft of blast media with 100 & 50 lbs of expandable -mineral abrasive.

- Quill Falcon Industries have re-engineered its Quill Falcone Cyclone 60 to Cyclone 30 to be lighter and more movable.

DETAILED SEGMENTATION OF THE GLOBAL SAND BLASTING MACHINES MARKET INCLUDED IN THIS REPORT

This research report on the global sand blasting machines market has been segmented and sub-segmented based on product, blasting type, end-user, and region.

By Product

- Portable Sand Blasting Machine

- Mini Sand Blasting Machine

By Blasting Type

- Dry

- Wet

By End-User

- Automotive

- Construction

- Marine

- Oil and Gas

- Petrochemical

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Frequently Asked Questions

What are the key drivers of growth in the global sand blasting machines market?

The key drivers include increasing demand for sand blasting in automotive, construction, and metalworking industries, advancements in technology, and rising awareness about surface treatment processes.

What are the major challenges faced by the sand blasting machines market?

Major challenges include stringent environmental regulations, high operational costs, and the health risks associated with silica dust exposure. Developing safer and more efficient alternatives also poses a challenge.

What technological advancements are impacting the sand blasting machines market?

Technological advancements such as automation, remote monitoring, and the development of eco-friendly abrasives are significantly impacting the market. These innovations are improving efficiency, safety, and environmental compliance.

How are environmental regulations influencing the sand blasting machines market?

Environmental regulations are pushing manufacturers to develop more environmentally friendly machines and processes. This includes the use of alternative abrasives, dust collection systems, and water-based blasting techniques to minimize environmental impact.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]