Global Rotary Tablet Press Market Size, Share, Trends, & Growth Forecast Report – Segmented By Type (Single Rotary Tablet Press, Double Sided Rotary Tablet Press), Application (Pharmaceuticals, Nutraceuticals, Cleaning Products, Industrial Pellets, Cosmetics) & Region - Industry Forecast From 2024 to 2032

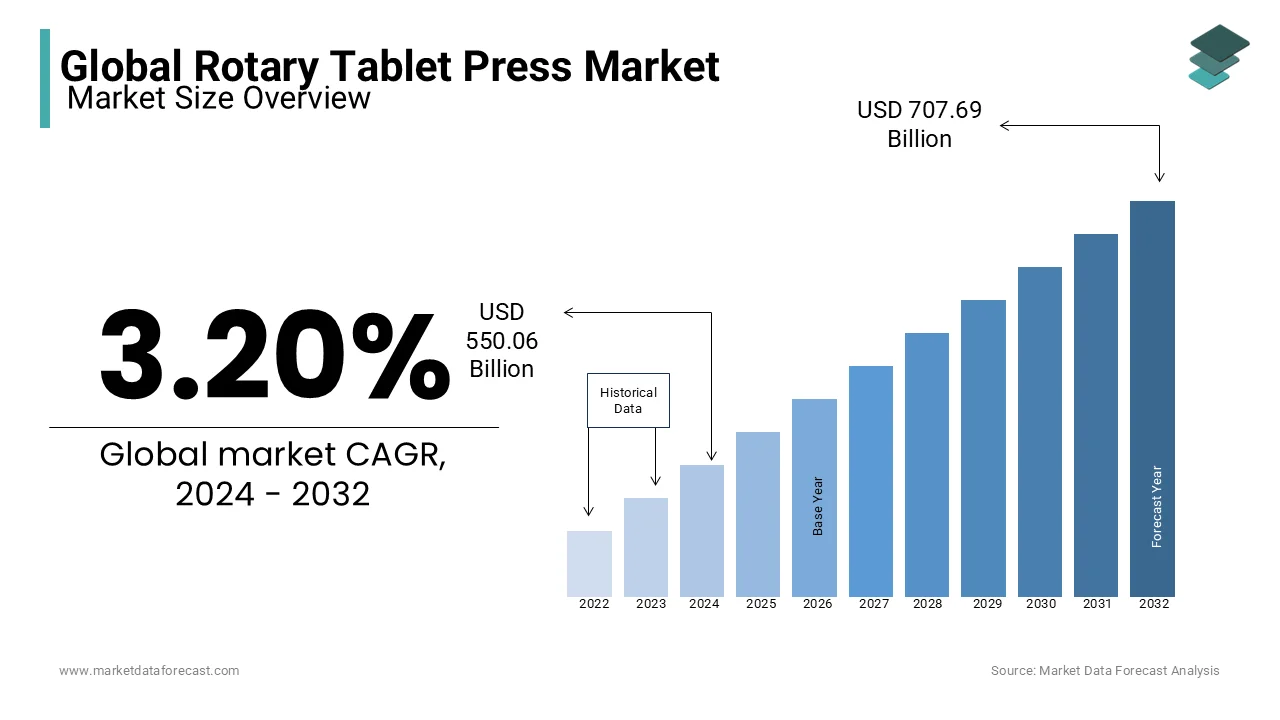

Global Rotary Tablet Press Market Size (2024-2032)

The Global Rotary Tablet Press Market was worth USD 533 billion in 2023 and is anticipated to reach a valuation of USD 707.69 billion by 2032 from USD 550.06 billion in 2024 and is predicted to register a CAGR of 3.20% during the forecast period 2024 to 2032.

Current Scenario of the Global Rotary Tablet Press Market

A tablet press (also known as a tablet pressing machine) is a machine that compresses powder or granules into tablets or pills. The tablet pressing machine may make pharmaceuticals, nutraceuticals, cleaning goods, industrial pellets, and cosmetics into tablets. The granulated powder must be measured into a cavity created by two punches and a die, and the punches must then be slammed together with considerable power to compress the powder into a tablet. Single-punch and rotational tablet presses are the two types of tablet presses. A rotary tablet press machine is a mechanical device that rotates multiple tooling stations to compress granules/powder combinations into tablet and pill forms.

The size, shape, and weight of the punch are determined by the punched design. The rotary tablet compression machine was designed to dramatically increase tablet production. The Rotary Tablet Press Machine has a number of advantages, including high capacity using multiple stations and minimal labour, output ranging from 9000 to millions of tablets/hour for mass production, rotary press reduces formulation waste, lowering production costs, and the compression cavity is automatically controlled. The equipment controls the weight and hardness of the tablets during compression to make the process easier.

MARKET GROWTH

In the coming years, demand from the pharmaceutical, nutraceuticals, cleaning products, industrial pellets, and cosmetics industries is expected to drive the global rotary tablet press market.

MARKET DRIVERS

The rotary tablet press market is predicted to grow in the coming years as investors raise their R&D investments to produce revolutionary tablet-based pharmaceutical treatments.

Furthermore, manufacturers seek to expand their factories in order to boost their production capacity, which might contribute to further growth in the rotary tablet press market in the future years. The pharmaceutical business, which is founded on research, plays a unique role in developing new medicines and tablets to treat and prevent a variety of health problems. Rotary Tablet Press Machine is used in the pharmaceutical and nutraceutical, food and confectionery, electronic and chemical industries, and applications. Pharmaceutical and nutraceutical applications can use rotating tablet press machines to make pills, vitamin tablets, and any other type of medicine found in pharmacies.

Its applications include micro pills, candy pills, milk tablets, mint pills, bilayer tablets, effervescent tablets, and other food and confectionery products, as well as dishwashing tablets, detergent tablets, and other electronic and chemical products. The rotary tablet press market is predicted to grow in the coming years as investors raise their R&D investments to produce revolutionary tablet-based pharmaceutical treatments. The pharmaceutical business, in comparison to other high-tech industries, invests more in R&D, production, and overall expenditure each year. Furthermore, manufacturers seek to expand their factories in order to boost their production capacity, which might contribute to further growth in the Rotary Tablet Press Market in the future years.

MARKET RESTRAINTS

One of the primary drawbacks of this rotating tablet press kind of tablet press machine is its high purchasing price.

Another stumbling block is that a multi-station compression machine, with its multiple automated processes, necessitates some skill. Furthermore, manufacturers seek to expand their factories in order to boost their production capacity, which might contribute to further growth in the rotary tablet press market in the future years. This is a significant expansion prospect for the rotary tablet press business.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

3.20% |

|

Segments Covered |

By Product, Application, and Region. |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa. |

|

Market Leaders Profiled |

Korsch, Fette, IMA, Kilian, Manesty, Kikusui, ACG Worldwide, Fluidpack, and Others. |

SEGMENTAL ANALYSIS

Global Rotary Tablet Press Market Analysis By Product

The fundamental difference between a single tablet press and a double tablet press is that a single tooling mechanism is used in the small tablet press, whereas a double-sided rotating tablet press requires several tooling mechanisms to finish the process. A bi-layered system with an A.C. numerical drive fully acquires a single rotating tablet press machine. This lab press works in conjunction with the gravity loader, which can be used in place of a force loader. Double-sided rotary tablet press machines are used for a number of applications, including the creation of unique tablets and other cosmetics goods that require specialized pharmaceutical and manufacturing sectors. This machine is beneficial since it has a mechanism that enables it to work with a multi-tooling system.

Global Rotary Tablet Press Market Analysis By Application

In the anticipated timeframe, the pharmaceutical industry is expected to have the greatest CAGR. In a tablet press, the tablets are manufactured according to a specified design. Punches and dies on the device aid in the shape of the tablets. Rotating tablet presses are used to create tablets for a range of businesses, while medications and vitamins are the most common applications.

REGIONAL ANALYSIS

Over the period 2024-2032, in the future years, increased demand for rotary tablet presses is expected to propel the market, particularly in North America and Europe.

Increased spending in the pharmaceutical industry, increased competition, product launches, increased spending in the general industry, retrofitting and renovation of old technology, and increased adoption of the rotary tablet press in developing countries will all contribute to global market growth.

KEY PLAYERS IN THE GLOBAL ROTARY TABLET PRESS MARKET

Companies playing a prominent role in the global rotary tablet press market include Korsch, Fette, IMA, Kilian, Manesty, Kikusui, ACG Worldwide, Fluidpack, and Others.

RECENT HAPPENINGS IN THE GLOBAL ROTARY TABLET PRESS MARKET

- IMAGO is a Galenic software that is based on the current generation of IMA tablet press machines' unique Kortex-Max control system. IMAGO explores the world beyond Galen. IMAGO is a tool built for scientific individuals, created by a team of software, mechanical professionals, and those working in pharmaceutical tabletting R&D. It is a fully integrated platform that allows a large amount of data to be automatically retrieved, presented, aggregated and made ready for usage by the end user.

- Korsch is introducing a tablet press designed for large formats, deeper filling depths, and stronger compression forces in technical and chemical industries. The XT 600 HD double rotary tablet press, which will be available in the fall of 2020, combines important aspects of the company's established technology in a cost-effective platform. Its design keeps the company's interchangeable turret feature, and it can produce single-layer and bi-layer tablets at fast speeds.

DETAILED SEGMENTATION OF THE GLOBAL ROTARY TABLET PRESS MARKET INCLUDED IN THIS REPORT

This research report on the global rotary tablet press market has been segmented and sub-segmented based on product, application, and region.

By Product

- Single Rotary Tablet Press

- Double-Sided Rotary Tablet Press

By Application

- Pharmaceuticals

- Nutraceuticals

- Cleaning Products

- Industrial Pellets

- Cosmetics

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Frequently Asked Questions

What is Rotary Tablet Press machines used for?

A rotary tablet press (also known as a tablet pressing machine) is a machine that compresses powder or granules into tablets or pills.

What is a major factor effecting the Rotary Tablet Press market growth?

The Rotary Tablet Press Market is predicted to grow in the coming years as investors raise their R&D investments to produce revolutionary tablet-based pharmaceutical treatments.

Name any three Rotary Tablet Press market key players?

Korsch, Fette and IMA are the three Rotary Tablet Press key players.

What is the major restraining factor in the global Rotary Tablet Press market?

The high purchasing price of the machine and need for skilled labour to operate the machine is blocking Global Rotary Tablet Press market growth.

Which industries majorly use the Rotary Tablet Press machines?

Rotary Tablet Press Machine is used in the pharmaceutical and nutraceutical, food and confectionery, electronic and chemical industries, and applications.

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]