North America Ceramic Coating Market Size, Share, Trends & Growth Forecast Report By Product (Oxide, Carbide, Nitride), Technology, Application, and Country (The United States, Canada and Rest of North America), Industry Analysis From 2024 to 2033

North America Ceramic Coating Market Size

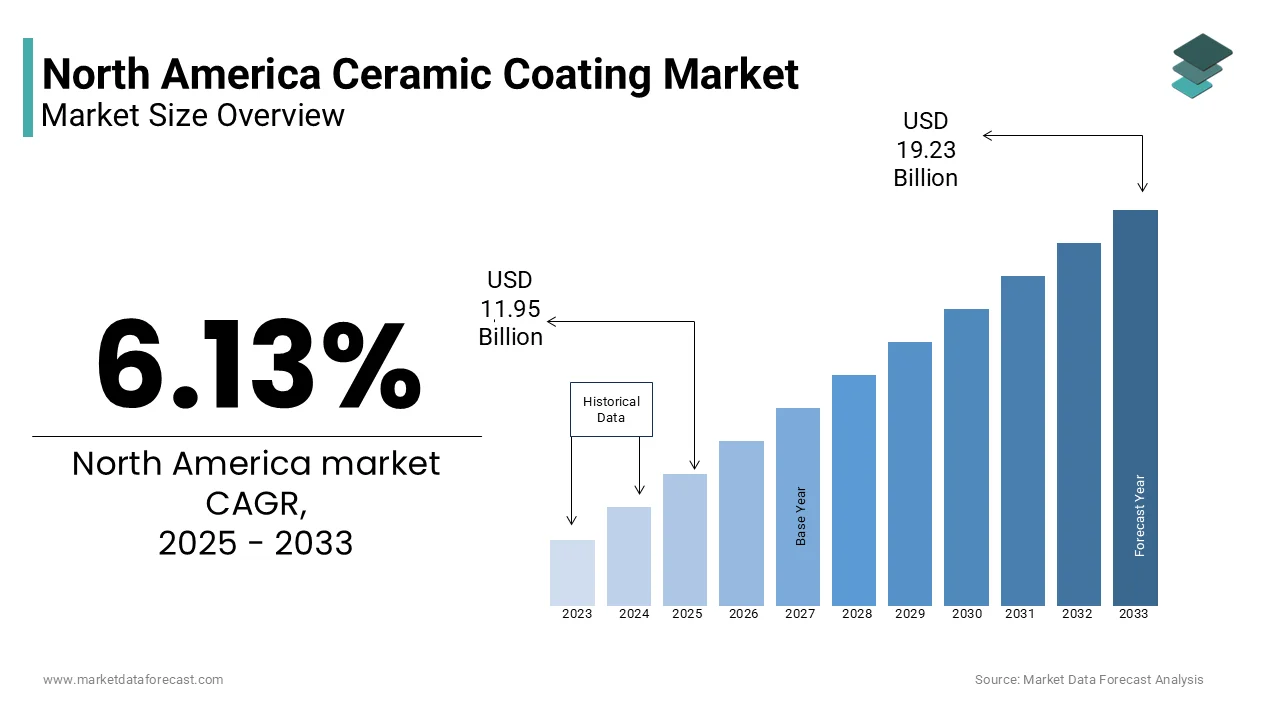

The Ceramic Coating market size in North America was valued at USD 11.26 billion in 2024 and is predicted to be worth USD 19.23 billion by 2033 from USD 11.95 billion in 2025 and grow at a CAGR of 6.13% from 2025 to 2033.

The North America ceramic coating market is a cornerstone of advanced material solutions with its widespread adoption across industries such as aerospace, automotive, and healthcare. The rising consumer awareness about sustainable and eco-friendly materials further bolsters market growth. However, economic uncertainties are fluctuating raw material prices, and regulatory challenges pose hurdles, necessitating adaptive strategies from manufacturers.

MARKET DRIVERS

Increasing Demand for High-Performance Materials in Aerospace

The aerospace industry serves as a primary driver for the North America ceramic coating market, fueled by the growing demand for lightweight yet durable materials capable of withstanding extreme temperatures. Ceramic coatings, particularly zirconia-based formulations, are extensively used in jet engines to reduce heat transfer and improve fuel efficiency. For instance, General Electric’s LEAP engine utilizes ceramic matrix composites (CMCs) to achieve a reduction in fuel consumption. Additionally, government initiatives like NASA’s Advanced Air Mobility program promote the use of innovative materials is stimulating demand for ceramic coatings.

Growing Adoption in Automotive Applications

The automotive sector represents another significant driver, with ceramic coatings increasingly adopted for their ability to enhance performance and aesthetics. According to the International Organization of Motor Vehicle Manufacturers (OICA), North America produced over 12 million vehicles in 2023, reflecting steady growth in manufacturing activity. Ceramic coatings are favored for their scratch-resistant, hydrophobic, and UV-protective properties by making them ideal for luxury car finishes and under-the-hood components. For example, Tesla’s Model S Plaid uses ceramic-coated brake rotors to withstand high temperatures during performance driving by enhancing durability and safety. Furthermore, rising consumer preferences for customization and premium finishes drive demand in the aftermarket segment.

MARKET RESTRAINTS

High Production Costs and Price Sensitivity

One significant restraint facing the North America ceramic coating market is the high production costs associated with advanced formulations and application processes. According to Plastics Today, the cost of raw materials like zirconia and alumina surged by 20% in early 2023 due to supply chain disruptions and geopolitical tensions. Such volatility impacts profit margins, forcing manufacturers to either absorb additional expenses or pass them on to consumers, potentially dampening demand. Smaller players with limited financial resilience face greater difficulties navigating these uncertainties, intensifying competitive pressures. Price sensitivity in cost-conscious industries like automotive further complicates adoption by necessitating strategic pricing models to sustain growth.

Stringent Environmental Regulations

Stringent environmental regulations governing chemical usage and waste management present another hurdle for the ceramic coating market. Regulatory bodies like the EPA mandate strict adherence to emission standards by compelling manufacturers to invest heavily in compliance measures. For example, California’s Proposition 65 requires explicit labeling of hazardous substances, adding complexity to product development. Non-compliance risks hefty fines and reputational damage. As per the Vinyl Institute, regulatory compliance costs account for approximately 15% of total production expenses. These financial burdens constrain innovation budgets and slow down market responsiveness for smaller firms lacking robust infrastructure. Balancing regulatory requirements with cost efficiency remains a persistent challenge for industry participants.

MARKET OPPORTUNITIES

Expansion into Emerging Industrial Applications

A burgeoning opportunity lies in expanding ceramic coating usage into emerging industrial applications in renewable energy and healthcare. According to the International Energy Agency (IEA), solar power installations in North America increased by 25% annually between 2021 and 2023 by driving demand for coatings that enhance photovoltaic cell efficiency. Ceramic coatings are increasingly used in solar panels to reduce reflectivity and improve light absorption by aligning with sustainability goals. Similarly, in the healthcare sector, antimicrobial ceramic coatings are gaining traction for their ability to prevent infections on medical devices and implants. Government incentives for green technologies, such as tax credits for renewable energy projects, further stimulate adoption.

Technological Advancements in Nanocoatings

Technological advancements in nanocoatings present another promising avenue for market growth. Innovations in nanostructured ceramics enable the development of next-generation coatings with enhanced performance characteristics, such as self-cleaning and anti-corrosion properties. According to McKinsey & Company, companies adopting advanced manufacturing processes achieve up to a 30% reduction in operational costs while improving product quality. These innovations cater to niche applications, including underwater structures and high-temperature industrial equipment, addressing unmet needs in specialized sectors. Additionally, digital tools like AI-driven predictive maintenance systems optimize coating lifespan by ensuring consistent performance.

MARKET CHALLENGES

Intense Competition from Alternative Coatings

Intense competition from alternative coatings poses a significant challenge for the ceramic coating market. Traditional options like polymer and metallic coatings remain popular due to their lower cost and familiarity among manufacturers. According to Floor Covering Weekly, traditional coatings accounted for nearly 40% of total sales in 2023. Similarly, advancements in bio-based alternatives, derived from renewable resources, threaten to disrupt the dominance of synthetic materials. Consumer skepticism regarding the long-term performance of newer formulations further complicates adoption. Smaller manufacturers face difficulties competing with established brands, particularly in price-sensitive markets. Differentiating products through superior performance and sustainability attributes remains critical for overcoming this challenge.

Economic Uncertainty and Project Delays

Economic uncertainty and project delays hinder the growth of the ceramic coating market, particularly during periods of inflation and interest rate hikes. According to the National Bureau of Economic Research, industrial project cancellations increased by 12% in 2023 due to rising financing costs and budget constraints. These delays disrupt supply chains and create inventory backlogs, impacting manufacturers’ profitability. Additionally, labor shortages exacerbate project timelines, further delaying material procurement. For instance, the Associated General Contractors of America reported a 15% shortfall in skilled labor by limiting the pace of infrastructure development. Navigating these economic headwinds requires strategic planning and collaboration with stakeholders to ensure timely execution of projects and sustained demand for ceramic coatings.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 to 2033 |

|

Base Year |

2024 |

|

Forecast Period |

2025 to 2033 |

|

CAGR |

6.13% |

|

Segments Covered |

By Product, Technology, Application, and Region |

|

Various Analyses Covered |

Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regions Covered |

The United States, Canada, Mexico, and Rest of North America |

|

Market Leaders Profiled |

A&A Thermal Spray Coatings, APS Materials, Praxair S.T. Technology, Saint-Gobain, Bodycote, Aremco Products, Kurt J. Lesker Company, OC Oerlikon, Fosbel, Swain Tech Coatings, Waipolon International, Integrated Global Services, and others |

SEGMENTAL ANALYSIS

By Product Insights

The oxide coatings segment led the North America market with an estimated share of 55.4% in 2924 due to their superior thermal resistance and durability, which is making them ideal for high-temperature applications such as turbine blades and exhaust systems. Zirconia-based oxide coatings, in particular, are widely used in the aerospace and automotive industries due to their ability to reduce heat transfer and enhance fuel efficiency. Technological advancements have enabled the development of customized formulations tailored to specific applications. For example, Praxair Surface Technologies’ zirconia coatings offer enhanced thermal stability and corrosion resistance by appealing to engineers and contractors alike. Urbanization trends and government-funded infrastructure projects further propel the growth of the segment.

The nitride coatings segment exhibit the CAGR of 9.8% from 2025 to 2033. This rapid growth is fueled by their exceptional hardness and wear resistance by aligning with sustainability goals and gaining traction among environmentally conscious consumers. Government incentives for green building projects further stimulate adoption. For instance, the Canada Greener Homes Grant program promotes the use of sustainable materials by indirectly boosting nitride coating demand. Additionally, advancements in coating technologies have improved aesthetic appeal and corrosion resistance by addressing earlier concerns about limited design options.

By Technology Insights

The thermal spray technology segment was the largest with a dominant share of the North America ceramic coating market in 2024 with its versatility and cost-effectiveness that makes it suitable for diverse applications across industries such as aerospace, automotive, and healthcare. Thermal spray coatings are widely used in turbine engines to provide thermal insulation and enhance durability, reducing maintenance costs and improving performance. Urbanization trends and rising disposable incomes further amplify demand in metropolitan areas. Additionally, the growing trend of DIY home improvement projects, supported by online tutorials and e-commerce platforms, has simplified access to thermal spray coatings by enabling homeowners to undertake projects independently.

The Physical Vapor Deposition (PVD) segment is estimated to register a CAGR of 10.5% in the next coming years. The growth of the segment is propelled by increasing investments in precision engineering and electronics manufacturing, requiring ultra-thin and highly durable coatings. PVD coatings are known for their superior adhesion and uniformity, are extensively used in semiconductor fabrication and medical device manufacturing to ensure consistent performance. Technological advancements enabling energy-efficient and fire-resistant formulations further enhance its appeal. Additionally, climate change concerns drive the adoption of resilient materials, particularly in hurricane-prone regions like Florida and Texas.

By Application Insights

The energy applications segment was accounted in holding 50.4% of the North America ceramic coating market share in 2024 with the widespread adoption in renewable energy projects and fossil fuel-based power generation. Solar panels, wind turbines, and gas turbines require advanced ceramic coatings to enhance efficiency and durability by driving demand for zirconia and alumina-based formulations. Urbanization trends and rising disposable incomes further amplify demand in metropolitan areas. Additionally, government incentives for green energy projects, such as tax credits for solar panel installations, indirectly stimulate demand for ceramic coatings.

The healthcare applications segment is projected to exhibit a CAGR of 11.2% in the next coming years. The growth of the market is propelled by increasing investments in medical device manufacturing and implantable technologies by requiring antimicrobial and biocompatible coatings. Ceramic coatings, known for their superior durability and corrosion resistance, are extensively used in surgical instruments and orthopedic implants to ensure consistent performance. Technological advancements enabling bioactive and self-healing formulations further enhance its appeal. Additionally, aging populations and rising healthcare expenditures drive the adoption of advanced materials in developed regions like the United States and Canada.

REGIONAL ANALYSIS

The United States was the largest contributor for the North America ceramic coating market, with 75.3% of share in 2024 with a confluence of factors, including robust industrial investments, technological advancements, and stringent regulatory frameworks promoting energy-efficient materials. Key industries such as aerospace, automotive, and renewable energy are the primary drivers of demand for advanced ceramic coatings. For instance, the U.S. aerospace sector, which grew by 6% annually between 2021 and 2023, relies heavily on thermal barrier coatings for jet engine components by driving innovation in zirconia-based formulations. Additionally, California’s dominance in green building initiatives, such as Proposition 65, has created a thriving market for eco-friendly ceramic coatings used in solar panels and medical devices. According to Statista, the U.S. produced over 12 million vehicles in 2023 by amplifying demand for scratch-resistant and hydrophobic coatings in the automotive industry. Rising consumer awareness about customization and premium finishes has also bolstered growth in the aftermarket segment. Collectively, these dynamics ensure sustained growth prospects for the U.S. ceramic coating market.

Canada was attributed in holding 14.3% of the North America ceramic coating market share in 2024 with its focus on sustainability and energy-efficient technologies. Advanced ceramic coatings, particularly nitride and oxide formulations will gain traction in provinces like Ontario and British Columbia due to their ability to enhance thermal efficiency and durability. Government-backed retrofitting schemes, such as the Canada Greener Homes Grant program, incentivize the use of sustainable materials, indirectly boosting ceramic coating adoption. Additionally, Canada’s cold climate necessitates thermally efficient solutions by making ceramic coatings indispensable for industrial equipment and infrastructure projects. Strategic partnerships between local manufacturers and international players enhance product availability and affordability by ensuring sustained growth in the Canadian market.

KEY MARKET PLAYERS

A&A Thermal Spray Coatings, APS Materials, Praxair S.T. Technology, Saint-Gobain, Bodycote, Aremco Products, Kurt J. Lesker Company, OC Oerlikon, Fosbel, Swain Tech Coatings, Waipolon International, Integrated Global Services, A.W. Chesterton, and DuPont are the key players in the North America ceramic coating market

The North America ceramic coating market is characterized by intense competition, with leading players vying for market share through innovation, strategic alliances, and customer-centric services. The landscape is dominated by giants like Praxair Surface Technologies, Saint-Gobain, and APS Materials Inc., each employing unique strategies to differentiate themselves. Praxair’s emphasis on technological advancements and sustainability sets it apart, while Saint-Gobain’s focus on specialized applications and customization resonates well with engineers and contractors. APS’s commitment to customer-centric solutions and bio-based alternatives addresses niche market needs in residential and industrial applications. Despite occasional price wars, value-added features such as enhanced durability, energy efficiency, and compatibility with green building practices mitigate margin pressures. Continuous investment in R&D ensures that companies stay ahead of evolving consumer preferences with the growing demand for eco-friendly and high-performance materials. Smaller players face challenges competing with established brands but often carve out niches by focusing on specialized applications or localized markets.

TOP PLAYERS IN THE MARKET

Praxair Surface Technologies

Praxair Surface Technologies reigns supreme as the leading player in the North America ceramic coating market. Renowned for its innovative zirconia-based formulations, Praxair leverages cutting-edge technologies to deliver high-performance solutions tailored to diverse applications. The company’s focus on sustainability is evident in its efforts to develop recyclable and energy-efficient products, appealing to environmentally conscious consumers. For instance, Praxair’s ZircoFlex series, introduced in 2023, offers enhanced thermal resistance and corrosion protection by making it ideal for aerospace and industrial applications. Strategic partnerships with contractors, architects, and builders enhance its reach across North America. Furthermore, Praxair’s commitment to R&D ensures continuous innovation, addressing evolving consumer needs and maintaining its dominance position in the competitive landscape.

Saint-Gobain

Saint-Gobain secures the second spot with its NorCoat series, Saint-Gobain focuses on developing customized ceramic coatings for specialized applications, including aerospace, healthcare, and renewable energy. The company’s commitment to R&D ensures continuous innovation, addressing unmet needs in niche segments. For example, Saint-Gobain’s bioactive coatings are extensively used in orthopedic implants, catering to the growing demand for biocompatible materials in the healthcare sector. Saint-Gobain’s global distribution network amplifies its market penetration, solidifying its prominence position. Additionally, the company’s sustainability-focused initiatives, such as reducing carbon emissions in production processes, resonate well with eco-conscious stakeholders. Strategic acquisitions and collaborations further strengthen its competitive edge, ensuring sustained growth in the North America market.

APS Materials Inc.

APS Materials Inc. is a flagship brand that offers superior durability and aesthetic appeal by making it a preferred choice for residential and commercial projects. APS’s acquisition of Guardian Glass in 2022 expanded its portfolio of sustainable ceramic coatings, reinforcing its competitive edge. The company’s focus on customer-centric solutions is evident in its tailored formulations for specific applications, such as antimicrobial coatings for medical devices and UV-protective coatings for automotive finishes. Additionally, APS’s commitment to sustainability aligns with global trends, as seen in its efforts to develop bio-based alternatives and reduce environmental impact. Strategic partnerships with distributors and contractors enhance its reach across North America by ensuring consistent growth and market position.

TOP STRATEGIES USED BY KEY PLAYERS

Key players in the North America ceramic coating market employ a variety of strategies to maintain their competitive edge and expand their market presence. Mergers and acquisitions remain a cornerstone strategy, enabling companies to broaden their product portfolios and enter new markets. For instance, APS Materials Inc.’s acquisition of Guardian Glass in 2022 enhanced its capabilities in sustainable ceramic coatings by addressing growing consumer demand for eco-friendly solutions. Product innovation is another critical tactic, with companies introducing next-generation formulations tailored to specific applications. Praxair’s launch of ZircoFlex exemplifies this approach, offering superior performance attributes that cater to industries requiring high thermal resistance. Geographic expansion is equally vital, with manufacturers targeting underserved regions through strategic partnerships and distribution networks. Sustainability-focused initiatives also play a pivotal role, as seen in Saint-Gobain’s efforts to develop energy-efficient formulations and reduce carbon emissions. Digital transformation further amplifies competitiveness, with companies leveraging AI-driven quality control systems and online platforms to streamline operations and engage customers. These multifaceted strategies ensure sustained growth and resilience amidst evolving market dynamics.

RECENT HAPPENINGS IN THE MARKET

- In March 2023, Praxair Surface Technologies launched ZircoFlex, offering enhanced thermal resistance and corrosion protection. This product introduction expanded Praxair’s offerings and addressed consumer demands for superior performance in extreme temperature environments.

- In June 2023, Saint-Gobain partnered with Habitat for Humanity, donating over 1 million square feet of ceramic coatings for affordable housing projects across North America. This initiative not only supported community development but also enhanced Saint-Gobain’s brand visibility and reputation.

- In September 2023, APS Materials Inc. acquired Guardian Glass, a leader in sustainable ceramic coatings. This acquisition broadened APS’s product range by enabling it to offer comprehensive eco-friendly solutions for modern construction needs.

- In December 2023, IKO Industries introduced Dynasty coatings, featuring advanced UV protection and thermal insulation properties. This launch aligned with growing consumer demand for durable and energy-efficient ceramic coatings by reinforcing IKO’s commitment to innovation.

- In February 2024, TAMKO Building Products implemented AI-driven quality control systems across its production facilities. This technological upgrade improved operational efficiency, reduced waste, and ensured consistent product quality by strengthening TAMKO’s competitive position in the market.

MARKET SEGMENTATION

This research report on the North America ceramic coating market has been segmented and sub-segmented based on the following categories.

By Product

- Oxide

- Carbide

- Nitride

- Other

By Technology

- Thermal Spray

- Physical Vapor Deposition

- Chemical Vapor Deposition

- Other

By Application

- Transportation & Automotive

- Energy

- Aerospace & Defense

- Industrial goods

- Healthcare

- Others

By Country

- The United States

- Canada

- Rest of North America

Frequently Asked Questions

1. What are the key opportunities in the North America Ceramic Coating Market?

Key opportunities include increasing adoption of ceramic coatings in the automotive, aerospace, and energy sectors due to their superior thermal resistance, durability, and corrosion protection—along with growing use in electronics, healthcare devices, and renewable energy components.

2. What are the major challenges facing the North America Ceramic Coating Market?

The market faces challenges such as high costs of raw materials and application technologies, complex coating processes, and regulatory concerns over emissions and worker safety during high-temperature coating applications.

3. Who are the major players in the North America Ceramic Coating Market?

Prominent players include Praxair Surface Technologies, Bodycote, Saint-Gobain, Aremco Products Inc., and APS Materials Inc., all of which offer advanced ceramic coating solutions for industrial, defense, and consumer applications.

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2000

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]