Global Monoethylene Glycol (MEG) Market Size, Share, Trends & Growth Forecast Report - Segmented By Technology (Naphtha-Based, Coal-And Natural Gas-Based, Bio-Based MEG), Application (Fiber, PET, Film, Antifreeze & Coolant, And Other Industrial Applications), and Region (North America, Europe, Asia Pacific, Latin America, Middle east and Africa) – Industry Analysis (2025 to 2033)

Global Monoethylene Glycol (MEG) Market Size

The global Monoethylene Glycol (MEG) market size was valued at USD 32.35 billion in 2024, and the market size is anticipated to reach USD 57.16 billion by 2033 from USD 34.46 billion in 2025, growing at a CAGR of 6.53% from 2025 to 2033.

Current Scenario of the Global Monoethylene Glycol (MEG) Market

The monoethylene glycol is the most commonly used chemical intermediate which is extensively used in polyester resins and textile fibers. The monoethylene glycol is used as automotive antifreeze owing to its lower freezing point, which enhances its adoption in ventilation and air-conditioning systems. Monoethylene glycol is the primary raw material for producing polyethylene terephthalate (PET), which is in high demand in food and beverage packaging, such as polyester film and PET bottles. The global monoethylene glycol market has accounted for notable growth in the past years and is anticipated to have significant growth during the forecast period. The high purity of monoethylene glycol is essential for producing polyester fiber. The monoethylene glycol produced from the GC glycol is expected to have a higher purity of 99.9%, which is crucial in producing high-quality polyester fiber. The increased applications of monoethylene glycol in various industries, such as engine coolant in automotive electronic capacitors and textile and PEG production, are escalating the market growth opportunities.

MARKET OVERVIEW

Monoethylene glycol is also given the word ethylene glycol, which is sweet in the tasting, colorless, and odorless composite. Monoethylene glycol is obtained from ethylene, a downstream composite of crude oil and natural gas. It is a key raw material employed in different industrial implementations. It is broadly employed in the manufacturing of films, fibers, and polyester resin. It is also employed as a coolant composite, dewatering agent, aircraft deicer and anti-icer, anti-freeze, and chemical transmitter. MEG is gained through an industrial procedure from ethylene oxide that is hydrated through the thermal procedure. The ethylene employed in the production of MEG is produced by different sources like naphtha, synthesis gas, coal, and biomass, whereas gas-based technology is highly employed in the market. The call for the biomass-based production procedure for MEG is gaining popularity due to its renewability and decreasing dependence on naphtha and coal-based sources.

MARKET DRIVERS

One of the key factors driving the expansion of the global monoethylene glycol market is the rising call for PET resin, polyester fibers, and antifreeze. In addition to that, monoethylene glycol is a bio-degradable compound owing to which the aquatic organisms are less impacted. This factor is also attributed to the expansion of the global market. Exposure to MEG is very harmful to humans; ingestion of this may highly impact the kidneys, heart, and central nervous systems, which is hindering the expansion of the market.

The rising demand for non-ionic surfactants and Y-O-Y growth in the textile & fiber industries are further boosting the growth of the monoethylene glycol market. The rising employment of monoethylene glycol as a raw material for manufacturing polyester fiber and polyethylene terephthalate (PET) will probably boost the monoethylene glycol market. Enhanced standard of living, in addition to the modern fashion tendency of the customers for newly made attires, is estimated to drive the polyester fiber call, directly raising the product industry size in the foreseen period. The product further finds uses in many industrial employments like antifreeze, hydrate inhibitors in gas pipelines, and as a heat transfer agent, which is estimated to manufacture so many prospects from different end-use businesses.

MEG is one of the broadly employed raw materials for the making of polyester fibers and polyethylene terephthalate (PET) resins. PET resins are employed in the making of different products, including textiles, tire cords, PET bottles, and water containers. MEG is employed in so many applications like stabilizers against gel formation, heat transfer fluids (gas compressors, ventilating, procedure chillers, and also in air conditioning), and water-based formulations. The antifreeze grade MEG is initially employed in the making of automotive antifreeze and coolants. Monoethylene glycol is mainly employed in the making of PET and polyester resins. In addition to that, polyester fabrics are broadly employed in apparel, yarns and ropes, home furnishings, and other industrial applications like insulating tapes and conveyor belts.

MARKET RESTRAINTS

The major drawback of monoethylene glycol is that it is highly toxic to humans and animals, hampering the market growth. Ethylene glycol is fatal if it is ingested as it breaks down into toxic compounds that affect the CNS of the body, heart, and kidneys, limiting the market growth. There are increased concerns regarding environmental toxicity as it affects aquatic life and is fatal to animals and birds, which also causes long-term effects on animals. The rising environmental concerns are expected to hinder the global market growth. Another factor restraining the market growth is the difficulty in diagnosing ethylene glycol poisoning, which hampers market growth. The high costs and the price fluctuations regarding the availability of raw materials are other factors impeding the global market expansion. The presence of stringent regulations regarding the approval of the products and environmental factors act as challenges for the industrial players in the market expansion. The significant factor that restrains the market growth is the complications related to storage, as the major drawback is the crystallization at low temperatures and its lower ability to absorb heat.

MARKET OPPORTUNITIES

Monoethylene glycol is widely used in producing polyester fabrics, which are extensively used in the textile industry. The expansion of the textile industry and apparel production across the globe is expected to provide market growth opportunities in the coming years. The increased utilization of monoethylene glycol in home furnishings, carpets, and garment production propels the market growth. The rising investments in research and developmental activities to enhance the applications of monoethylene glycol are estimated to increase innovative product launches that augment the global market growth rate. The growing government support initiatives for the chemical sector are estimated to influence market growth positively. The monoethylene glycol is highly adopted for chemical use in suspension of conductive salt in electrolytic capacitors, promoting the market growth rate.

MARKET CHALLENGES

The major challenging factor is the degradation of monoethylene glycol in the presence of oxygen, which produces highly effective acids that can corrode metals and carbon steel. The monoethylene glycol is the major pollutant in most industries, such as polyfilm manufacturing, pharmaceuticals, and petroleum.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 to 2033 |

|

Base Year |

2024 |

|

Forecast Period |

2025 to 2033 |

|

CAGR |

6.53% |

|

Segments Covered |

By Technology, Application, and Region. |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe Asia Pacific, Latin America, Middle East & Africa. |

|

Market Leaders Profiled |

SABIC (Saudi Arabia), Formosa Plastic Group (Taiwan), The Dow Chemical Company (US), Sinopec (China), BASF, MEGlobal, Shell (Netherlands), Reliance Industries (India), SIBUR (Russia), ExxonMobil Corporation, Royal Dutch, Mitsubishi Chemical, LyondellBasell, AkzoNobel, Honam Petrochemical Corporation, Sinopec Zhenhai Refining & Chemical Company, and Others. |

SEGMENTAL ANALYSIS

By Technology

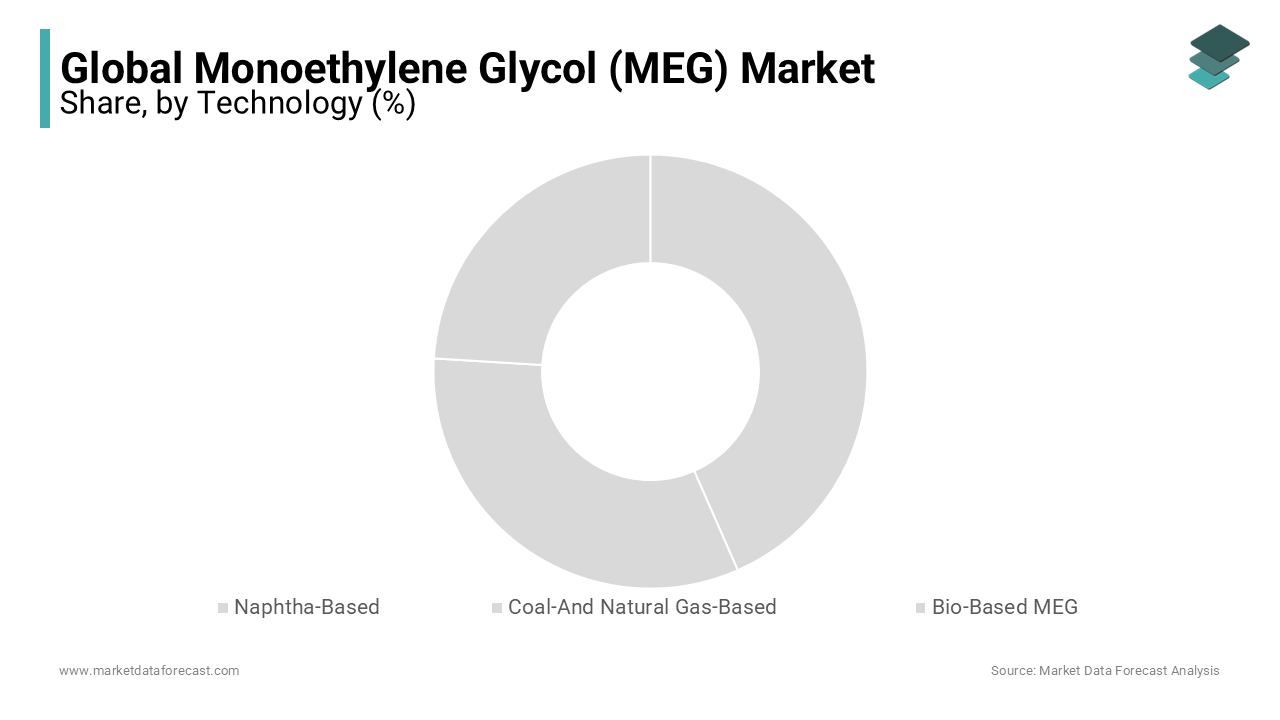

The Coal and Natural Gas-based segment is the leading category and is predicted to continue its consumption trend during the forecast period. The improved chemical reliability and durability, ease of recycling, strong resistance characteristics, and dimension stability are contributing to the segment’s growth. In April 2025 it was reported that India’s plastic exports had increased by 14 per cent in February 2025 regardless of resilience in merchandise shipments. The growing demand around the world for Indian goods, since other countries are looking for substitutes for Chinese plastic products, is contributing to the expansion of the regional and global monoethylene glycol market.

By Application

The PET segment holds the majority portion of the monoethylene glycol market share. This is because of the beneficial properties of MEG against other items in the manufacturing of PET. Moreover, the PET cost trajectory in the APAC showed mixed movement in the first and second quarters of 2024. Also, PET Resin prices experienced an upward trend in return for the suspected transition in demand in the region. In addition, after the Lunar New Year holidays in China PET exports surged. Whereas in North America and Europe, the pattern of importing recycled plastic from APAC is expected to strengthen the segment’s market share.

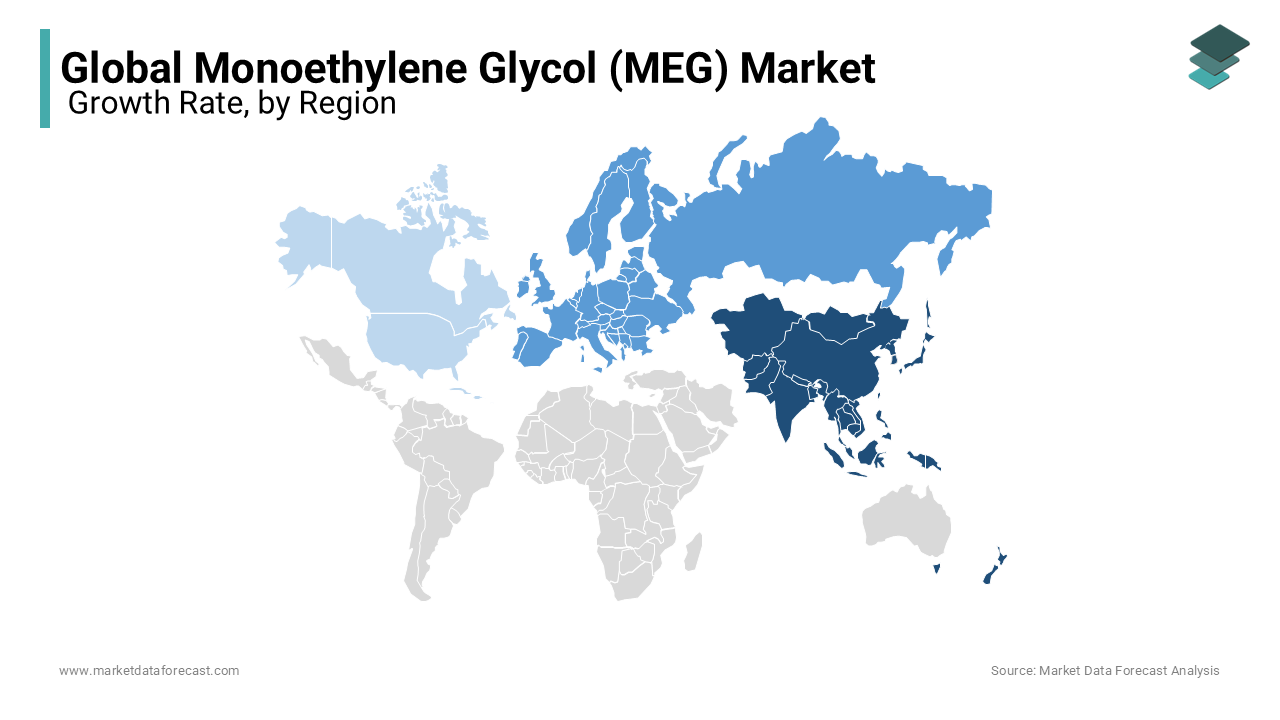

REGIONAL ANALYSIS

Asia-Pacific accounted for the most significant share of the worldwide market in 2024; China accounted for over 35.5% of the global market share. The regional market is estimated to show the highest CAGR during the foreseen period due to the growing textile and packaging businesses in the regional market. The packaging market in the region is the most significant worldwide. It is further determined to multiply due to the rise in per capita disposable expenditure and the increasing call for hygienic packaging in the pharmaceutical and food businesses. Also, the growth of the automotive business in the region is further estimated to propel regional market expansion. The automotive market in the economies of India, China, Japan, South Korea, and Thailand are estimated to be the key customers of the MEG in the regional market in the future. The enlarged textile sector in China is a significant factor propelling the regional market growth.

Europe is estimated to be the second biggest regional market and is mainly credited to the high call for bio-based MEG for the making of bio-PET. Rising employment of bio-PET in the packaging business in the regional market due to the strict environmental rules and the escalated emphasis on the shift from crude oil-obtained products to bio-based products which escalates the regional market growth.

The North American region is projected to register notable growth during the forecast period. The expanding textile industry and the increased utilization of monoethylene glycol in producing apparel and home furnishing products are boosting the regional market share growth. The enlarging export value of textile products from the region is the primary factor contributing to the regional market expansion. The United States industry has become the second-largest exporter of textile products globally.

KEY MARKET PLAYERS

Companies playing a prominent role in the global monoethylene glycol (meg) market include SABIC (Saudi Arabia), Formosa Plastic Group (Taiwan), The Dow Chemical Company (US), Sinopec (China), BASF, MEGlobal, Shell (Netherlands), Reliance Industries (India), SIBUR (Russia), ExxonMobil Corporation, Royal Dutch, Mitsubishi Chemical, LyondellBasell, AkzoNobel, Honam Petrochemical Corporation, Sinopec Zhenhai Refining & Chemical Company, and Others.

RECENT HAPPENINGS IN THE GLOBAL MARKET

- In April 2025, Glencore, a mining and commodities trading corporation, announced its plan to acquire Shell’s Singapore oil refinery and petrochemical plants. The UK-based oil company includes a refinery with 237,000 barrels per day capacity, a one-million-tonne-per-year ethylene plant on Bukom Island, and a mono-ethylene glycol manufacturing facility on Jurong Island.

- In November 2022, The government of Indi announced the anti-dumping probe on imports of monoethylene glycol at Reliance Industries.

- In January 2022, ExxonMobil and SABIC announced the startup of Gulf Coast Growth Venture’s top manufacturing facility in Texas. This new facility is estimated to include one mono-ethylene glycol unit with a 1.1 million metric tons annual capacity.

MARKET SEGMENTATION

This research report on the global monoethylene glycol (meg) market has been segmented and sub-segmented based on application, technology, and region.

By Technology

- Naphtha-Based

- Coal-And Natural Gas-Based

- Bio-Based MEG

By Application

- Fiber

- PET

- Film

- Antifreeze & Coolant

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]