Global Magnetic Separator Market Size, Share, Trends, & Growth Forecast Report - Segmented By Type (standalone magnetic separators, magnetic separator equipment), Magnetic Type (permanent magnets, electromagnets), Materials Type (dry, wet), Cleaning Type (automatic, manual), End-users (mining, ceramics and plastics, recycling, food and beverages, chemicals and pharmaceuticals, glass and textile, others), & Region - Industry Forecast From 2024 to 2032

Global Magnetic Separator Market Size (2024 to 2032)

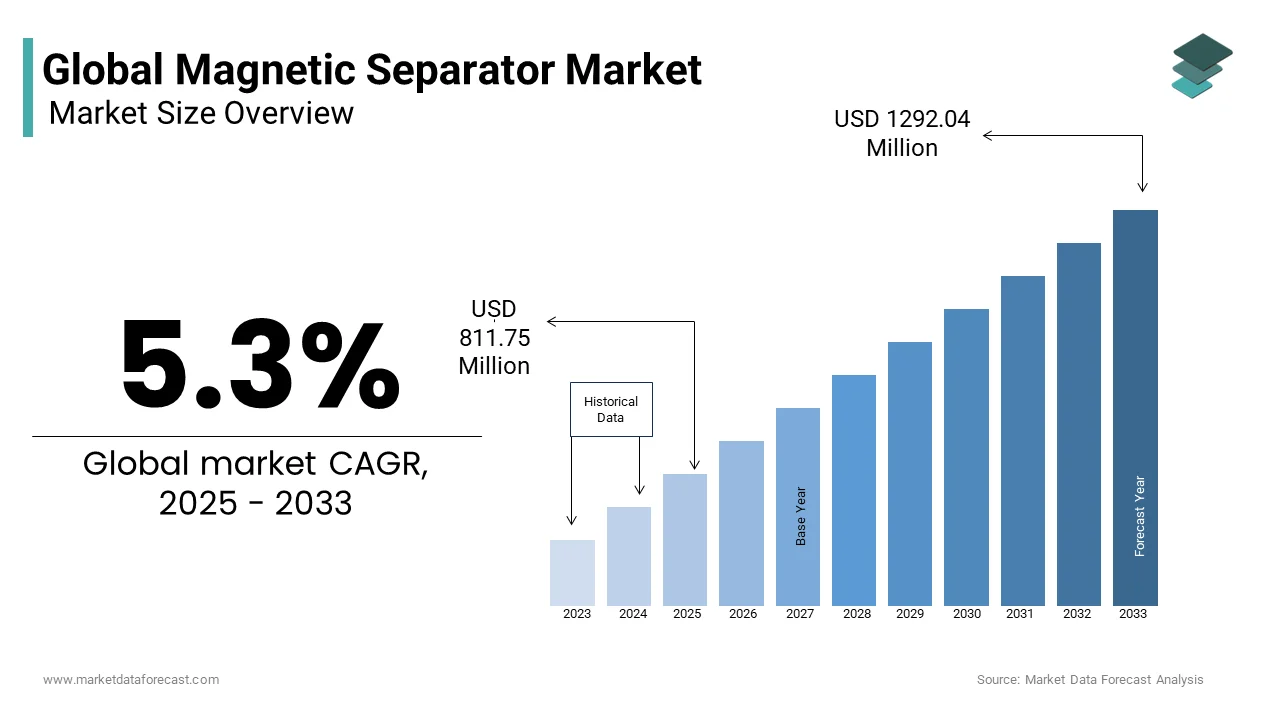

The size of the global magnetic separator market was valued at USD 770.89 million in 2023. The global market is expected to be worth USD 811.75 million in 2024 and USD 1,230 million by 2032, growing at a CAGR of 5.3% during the forecast period.

Current Scenario of the Global Magnetic Separator Market

Magnetic separation is an emerging technology that uses magnetism, which is used in combination with conventional separation and identification methods.

Magnetic separations in biotechnology have increased in recent years, leading to an astonishing variety of particles, affinity mechanisms, and processes. The magnetic separation technique is used to purify cells and biologically active compounds such as proteins and nucleic acid directly from raw samples.

In industries like mining and recycling, magnets play an important role. A magnetic separator helps attract magnetic particles such as impurities or ferrous minerals by generating a strong magnetic flux. A conveyor belt moving in an electric field is used to place the extracted minerals during the magnetic separation process. Thus, the ferrous particles are separated from the mixture of impurities and minerals when they adhere to the magnet. The other particles that are repelled by magnetic force are collected in separate collectors as they fall from the conveyor belt. Innovations in the electronic systems market will pave the way for better magnetic separators. The global market for magnetic separators is experiencing significant growth and will increase significantly in the coming years.

MARKET DRIVERS

The upward trajectory of world commodity prices has also boosted the mining industries, which have also increased the demand for magnetic separators.

The fate of the world market for magnetic separators is linked to that of the mining industry. Mining industries have experienced a streak due to industrialization and urbanization around the world, which in turn has driven the demand for magnetic separators. Another factor driving the global market for magnetic separators is the emergence of technologically improved magnetic separators with improved features that provide energy savings, automatic electromagnet cooling, and increased purification capacity that reduces maintenance and repair costs. Countering market growth is the massive expense required for research and development activities.

MARKET RESTRAINTS

However, the high cost of magnetic media and magnetic blocks is likely to hamper the growth of the global market for magnetic separators.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

5.3% |

|

Segments Covered |

By Type, Magnetic Type, Materials Type, Cleaning Type, End Users, and Region. |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

Douglas Manufacturing Co., Inc., Eriez Manufacturing Co., LONGi Magnet Co., Ltd., Metso Corporation, Mitsubishi Nagasaki Machinery, Noritke Co., Limited, Outotec Oyj, Steinert GmbH, thyssenkrupp AG, Yantai Xinhai Mining Machinery Co., Ltd. |

SEGMENTAL ANALYSIS

Global Magnetic Separator Market By Type

The equipment types segment had the largest market share in 2019 and is expected to remain dominant throughout the forecast period.

Contains drums, overbands, rollers, and eddy current separators. The growing demand from different industries such as mining, recycling, ceramics, paper and plastics is driving the growth of this segment. Equipment segment magnetic tape separators are expected to see the fastest growth during the forecast period as they are used to remove large volumes of iron particles from materials.

Global Magnetic Separator Market By Magnetic Type

Among them, electromagnets are used to remove large ferrous lumps from mineral gangue mixtures. Permanent magnets find application in the separation of stray ferrous particles from mineral ore. Once the collection of these particles is complete, non-metallic stainless steel is used to remove them from the magnets. Self-cleaning magnets rely on the combined technologies of electromagnets and permanent magnets. These magnets automatically remove and separate magnetic and non-magnetic particles from the mineral ore.

Global Magnetic Separator Market By Cleaning Type

The auto cleaning types segment had the largest market share in 2019 and is expected to remain dominant throughout the forecast period. They reduce or avoid the labor required to clean the magnetic separators and increase the efficiency of the production process. They are safer compared to the manual type of cleaning because metal contaminants are removed automatically. These factors are responsible for driving the automatic cleaning type segment market during the forecast period.

Global Magnetic Separator Market By End Users

On an end-user basis, biotech companies are expected to contribute a high revenue share in the global magnetic separator market. The food and beverage industry segment is expected to see growth at the highest CAGR during the forecast period. Magnetic separators help remove ferrous contaminants from food products which, if consumed, can be harmful to health. The demand for magnetic separators in the food and beverage industry is increasing due to an increase in food consumption, attributed to population growth, as well as the development of new rules and regulations by the food authorities (such as the Law Food Safety Modernization) to improve product quality.

REGIONAL ANALYSIS

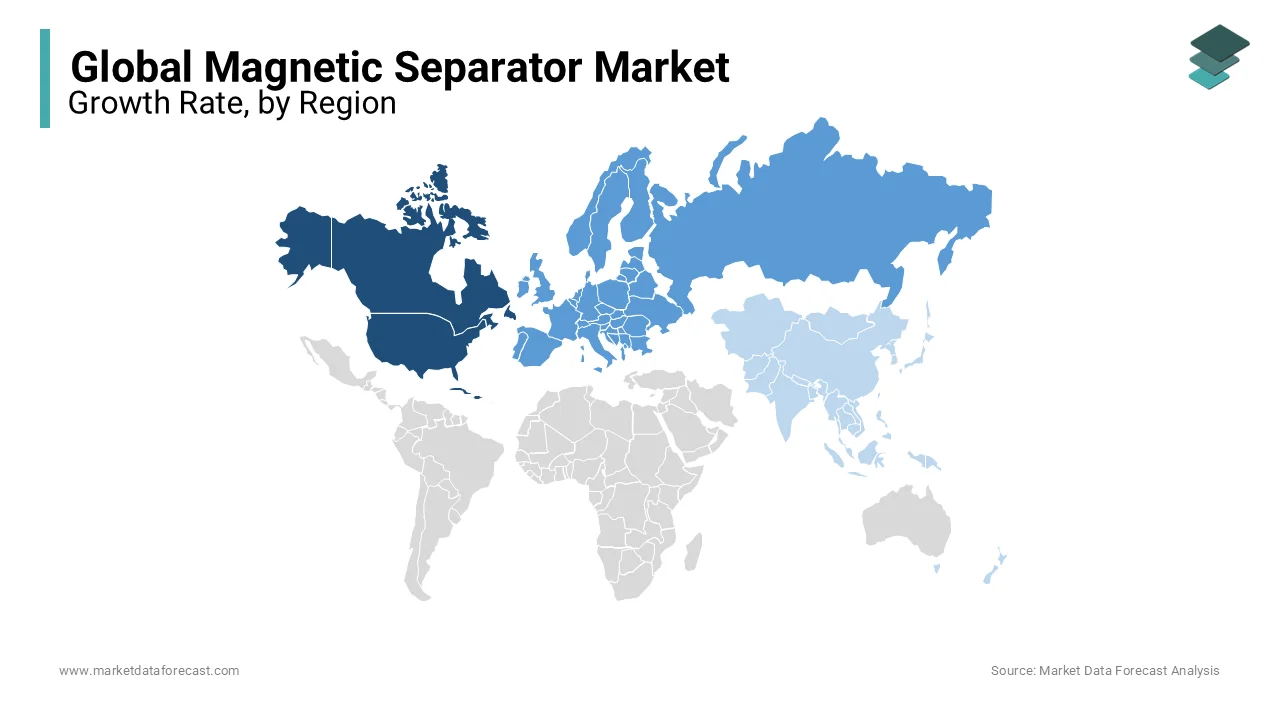

The magnetic separator market is also expected to grow rapidly in North America due to the rapid advancement of the automotive and renewable energy industries that require advanced tools and devices in their operations.

Europe, which is recovering from an economic downturn, is showing somewhat lackluster growth due to cautious investment in the market.

Among tAsiahem, -Pacific is a key market driven by the fast-growing developing economies of India and China, which have booming manufacturing sectors. These promote the rapid absorption of high quality mined minerals. Furthermore, the increasing radioactive mining activity in these countries will also promote the market for magnetic separators.

KEY MARKET PLAYERS

Major Key Players in the Global Magnetic Separator Market are Douglas Manufacturing Co., Inc., Eriez Manufacturing Co., LONGi Magnet Co., Ltd., Metso Corporation, Mitsubishi Nagasaki Machinery, Noritke Co., Limited, Outotec Oyj, Steinert GmbH, thyssenkrupp AG, Yantai Xinhai Mining Machinery Co., Ltd.

RECENT HAPPENINGS IN THE MARKET

- Metso Minerals will supply an iron ore upgrade plant to BMM Ispat Ltd's Hospet-Bellary mine in Karnataka, South India. Delivery will be completed by the end of 2010. The total value of the order is approximately 7 million euros.

- Magnetic separators to aid in metal recovery through Re-Gen waste enhancement.

- Magnetic separators from Douglas Manufacturing Co., based in Pell City, Alabama. They help avoid downtime and protect expensive processing equipment used to purify transported materials.

This research report on the global Magnetic Separator market has been segmented and sub-segmented based on type, magnetic type, materials type, cleaning type, end users, and region.

By Type

- Standalone Magnetic Separators

- Magnetic Separator Equipment

By Magnetic Type

- Permanent Magnets

- Electromagnets

By Materials Type

- Dry

- Wet

By Cleaning Type

- Automatic

- Manual

By End Users

- Mining

- Ceramics & plastics

- Recycling

- Food & Beverages

- Chemicals & Pharmaceutical

- Glass & Textile

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Frequently Asked Questions

What are the key drivers of growth in the global magnetic separator market?

Key drivers include increasing mining activities, growing recycling rates, advancements in magnetic separation technology, and the rising demand for high-purity materials in various industries.

What are the major applications of magnetic separators globally?

Major applications include recycling, mining, food and beverage processing, pharmaceuticals, and ceramics. These industries use magnetic separators to remove ferrous contaminants and ensure product purity.

How is technological innovation impacting the magnetic separator market globally?

Technological innovations such as the development of automated and efficient magnetic separators, integration with IoT for real-time monitoring, and advancements in magnetic materials are significantly enhancing market growth and operational efficiency.

How is the global magnetic separator market expected to evolve in the next five years?

The market is expected to witness significant growth, driven by increased investments in mining and recycling industries, technological advancements, and rising awareness about environmental sustainability.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]