Global Injection Molding Market Size, Share, Trends & Growth Forecast Report By Product Type (Plastic, Rubber and Metal), Machine Type (Hydraulic, All-Electric and Hybrid), End-Use Industry (Automotive, Packaging and Consumer Goods), Clamping Force (0-200, 201-500 and Above 500) and Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa), Industry Analysis (2024 to 2032)

Global Injection Molding Market Size (2024 to 2032)

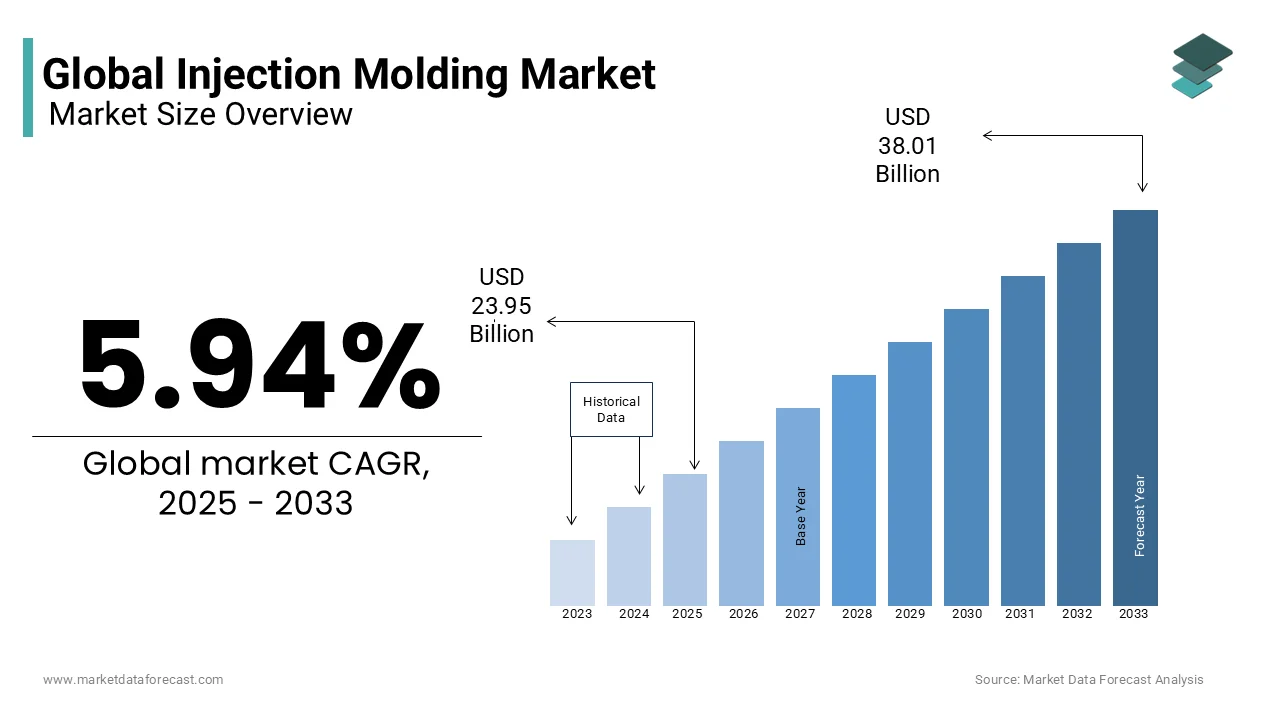

The global injection molding market size was valued at USD 21.34 billion in 2023. The global market is expected to be worth USD 22.61 billion in 2024 and USD 35.87 billion by 2032, growing at a CAGR of 5.94% from 2024 to 2032.

MARKET OVERVIEW

Injection molding equipment includes mechanical machines that utilize injection molding procedures to obtain injection-molded plastic goods. Injection molding equipment of various clamping force proportions with less than 200 tons force, 200 tons force to 500 tons force, and more than 500 tons force are present in the industry. Injection molding machines are used to manufacture goods such as plastics, rubber, metal, and ceramic. It is made of two major parts: an injection unit similar in purpose to an extruder and a clamping unit related to the working of the mold. The injection molding machine provides improved accuracy in making goods, enhanced flexibility, and a high level of energy efficiency in the procedure that assists in making a wide variety of goods.

The global injection molding market has experienced significant growth in the past years. The growing demand for injection molding equipment in end-use sectors like automotive, consumer goods, packaging, medical, electrical & electronics is raising the market revenue. The vast adoption of injection molding in packaging as plastic injection molding offers high-volume packaging to thin-wall containers and bottle molds, escalating the demand for injection molding machines and expanding market revenue. The consistent growth in the construction industry is expected to create opportunities for the injection molding market players in the coming years.

Current Scenario of the Global Injection Molding Market

Today, the injection molding market is experiencing a strong growth trajectory. Technological developments and heightened demand for plastic products, parts or components across several industries are influencing this progress. Moreover, it is a highly dynamic market, with new sustainable solutions and technologies becoming prominent every year. This would be clear from this fact.

- Annually, around 400 million tons of plastic waste are produced in the world, out of which about 60 per cent land up in the dumping grounds or environment, as per the UN Environment Programme.

Among the most impressive trends is the emergence of unique bio-based and sustainable plastic materials for moulding by injection, which takes the market forward. With increasing customer awareness towards the environment, brands and companies are answering by accepting eco-friendly materials such as polylactic acids (PLA), Polyhydroxyalkanoates (PHA), and Bio-PET.

MARKET DRIVERS

Growing Demand for Injection-Molded Plastic Goods Worldwide

In addition, an escalated focus on the employment of energy-efficient machines is predicted to boost the expansion of the global injection molding market. Also, advancements in the hybrid machine and the rise in employment of all-electric injection molding machines are predicted to boost the expansion of the worldwide injection molding machines industry in the future years. In addition, an increase in energy-saving awareness boosts the industry's expansion. Besides, higher production rates and fast manufacturing through injection molding are predicted to fuel the expansion of the worldwide industry. The expansion of the construction industry is majorly impacting the growth of the injection molding market due to broader adoption due to escalating infrastructure development projects and several technological breakthroughs. The escalating urban population escalated customer spending on packaged products, and the increase in e-commerce and well-established retail are contributing to the development of the packaging industry, which is contributing to the expansion of the injection molding market worldwide. The increasing competition among packaging makers has resulted in the adoption of various kinds of packaging. This is driving the industry for rigid plastic packaging and, in return, the call for injection molding machines from the packaging industry. The accelerating demand for automotive applications in North America and the Asia Pacific regions propels global market growth opportunities. The shift of manufacturers towards lightweight and electrified vehicles and the emerging applications of injection molding in the healthcare sector are estimated to create lucrative growth in the coming years.

Injection molding is highly employed in packaging plastic products like cups and containers. The primary driver for expanding the market is the increasing call for injection molded plastics in the automotive industry. This is credited to the latest implementations of these plastics to produce automobile components in an offer to decrease overall vehicle weight. There is an escalating fashion toward decreasing automobile weight to enhance fuel efficiency. Plastics are a significant part of the latest trend as they can offer high-weight deductions. Increasing preference for biodegradable polymers in medical device makers results in high expansion opportunities in the injection molded plastics market.

MARKET RESTRAINTS

High costs associated with the initial setup and tooling are majorly hindering the global injection molding market. Limited access to skilled labor, environmental concerns related to plastic waste, and fluctuations in the prices of raw materials are showing negative impacts on the global injection molding market expansion. Challenges in quality control and consistency, regulatory compliance and safety standards, and technological limitations in complex part production further impede global market growth. The presence of stringent environmental regulations leads to challenges for the manufacturers, which limits the adoption rate.

MARKET OPPORTUNITIES

Material innovations, new technological developments, evolving design, and sustainability provide potential opportunities for the expansion of the injection molding market. Materials like PLA, PHA, and Bio-PET are eco-friendly and are believed to significantly transform the market in the coming years. This is because PLA is made from plant starches such as potatoes and corn and is rapidly gaining biodegradable polymer. It allows for the creation of plastic products that have a reduced carbon footprint. Moreover, PHA are biodegradable polyesters, produced by microorganisms, that exhibit properties comparable to traditional plastics. These plastics are renewable materials and rely less on fossil fuels for production. Replacing standard PET plastic with bio-based PET. Therefore, the demand for these three materials is expected to escalate in future. Furthermore, the market is anticipated to witness further growth with high-performance plastics. These facilitate the creation of duration and lightweight parts across different industries, for example, electronics, medical, and aerospace. PEI and PEEK are such materials which broaden the design options for injection molded components.

Apart from materials, novel technologies are also transforming plastic forming procedures and abilities. This revolution can be attributed to automated production and 3D-printed molds. A small section of market players has already started using AI-powered systems and robotic arms to improve consistency, accuracy, and productivity in operations in this field. And, additive manufacturing is quickly getting popular and can provide swift prototyping of injection molds, at no expense of CNC machines and lead time. Hence, throughout the forecast period, these trends will expedite the market expansion.

MARKET CHALLENGES

Risky working conditions are one of the key challenges companies face in the injection molding market. Even after several benefits, there are risks inherent in the plastic making process. The management of hazards in this market is not just a regulatory need but a crucial business strategy. The unsafe working environment is a major danger to workers and the growth of the market. Accidents, burns, and fire and explosion hazards are some of the most common hazards which not only affect the company or organization financially but also leads to the loss of working days and production targets.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

5.94% |

|

Segments Covered |

By Type, Machine, Clamping Force, and Region |

|

Various Analyses Covered |

Global, Regional, & Country Level Analysis; Segment-Level Analysis; DROC, PESTLE Analysis; Porter’s Five Forces Analysis; Competitive Landscape, Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

Sumitomo Heavy Industries (Japan), Arburg (Germany), Nessei Plastic (Japan), Chen Hsong (China), Milacron (United States of America), The Japan Steel Works (Japan), Husky (Canada), Engel (Austria) and Haitian International (China) |

SEGMENTAL ANALYSIS

Global Injection Molding Market By Type Insights

The plastics segment dominated the global market revenue with a significant share. Plastics like ABS and HDPE are broadly accepted for employment in different end-use businesses like packaging, building, and automotive due to their high flexibility and features. Various plastic products using injection molding include needles, disposable razors, bottle lid closures, phone handsets, and dashboards. Injection molding is the most widely used manufacturing technique for producing plastic materials, driving the segment growth opportunities.

The metal segment is estimated to grow prominently during the forecast period as metals are resistant to corrosion and have superior surface finishes. Metal's various advantages, like its ability to manufacture parts with complex geometrics, are enhancing the demand for metal-molded components. The increasing costs of plastic recyclability allow manufacturers to switch to bioplastics and metals, fueling the segment's growth.

Global Injection Molding Market By Machine Insights

The All-electric segment holds a significant market share and is estimated to grow fastest during the forecast period. The machine operations are powered by an electric servo motor, which drives gears, racks, and ball screws in an all-electric injection molding machine. All-electric machines are quicker, quieter, and more precise than other molding machines, driving the adoption rate and leading to market growth. The all-electric machine requires less cold water and less cleaning and uses limited energy and oil with minimal preventive maintenance, which boosts the segment's growth in the forecast period.

Global Injection Molding Market By Clamping Force Insights

In these sectors, the more than 500 tons force sector holds a leadership position and is predicted to rise at a high expansion rate throughout the foreseen period, due to the rise in implementation of more than 500 tons force proposition to produce large injection molded plastic components.

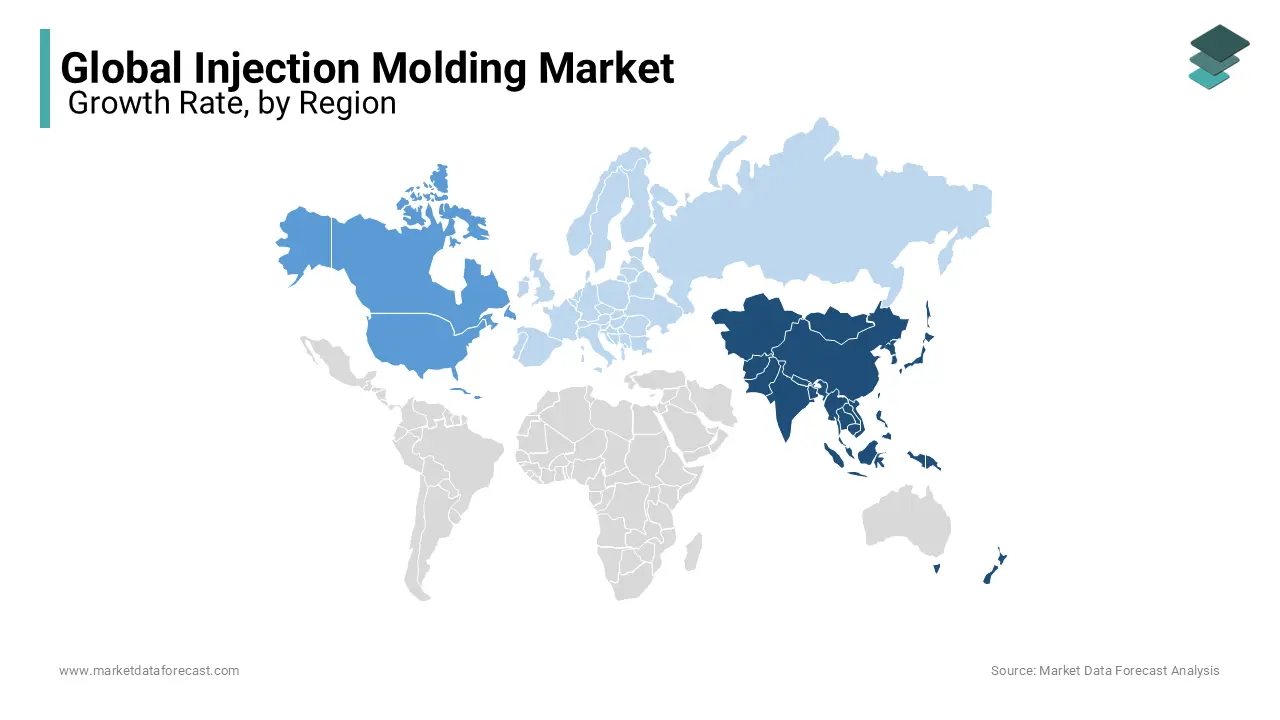

REGIONAL ANALYSIS

Asia-Pacific holds a significant share in the global injection molding market. It is predicted to rise at a high CAGR due to several small and mid-level market players in nations like China, Hong Kong, Japan, and India. The rapid expansion of manufacturing and processing industries and rising urbanization are expected to impact the market growth opportunities across the region positively. The presence of abundant raw materials and lower labour costs with increasing investments in packaging, medical, and electronics applications further boost the regional market expansion.

The North American region holds second place in global market revenue as it ensures high expansion opportunities in the electrical and electronics segment. The rise of different developed technologies in customer electronics has fuelled the adoption of smart devices, probably affecting industry expansion. The expanded healthcare in the region is raising the demand for medical injection molding devices, and the growing incorporation of robotics, IoT, and artificial intelligence is propelling the regional market growth.

- As per the Committee on Equipment Statistics (CES) under the Plastics Industry Association. In North America, there was a significant uptick in shipments of extrusion machinery and injection molding in the 4th quarter of 2022, with an estimated total value of shipment at 432.7 million dollars, representing a 22.3 per cent rise from 14.4 per cent decrease, and reflecting a 4.4 per cent growth compared to the same quarter last year.

Europe may record steady growth during the predicted forecast period due to the availability of large automotive-making hubs in the region. Escalating customer preference for lightweight auto parts to improve complete vehicle efficiency has fuelled the call for polymer & plastic composites, which is the major driving factor of the industry.

KEY MARKET PLAYERS

Companies playing a significant role in the global injection molding market include Sumitomo Heavy Industries (Japan), Arburg (Germany), Nessei Plastic (Japan), Chen Hsong (China), Milacron (United States of America), The Japan Steel Works (Japan), Husky (Canada), Engel (Austria) and Haitian International (China).

RECENT HAPPENINGS IN THE MARKET

- In October 2024, Milacron launched its latest fully electric machine for injection molding at Fakuma 2024. The machine utilises monosandwich technology. Moreover, it will facilitate the manufacturing of multiple-layer parts, by employing post-consumer recyclable (PCR) materials.

-

In June 2023, Haitian International opened an advanced manufacturing facility in Mexico with a strategic plan to enhance local production capacity, reduce delivery times, and deliver superior solutions.

- In August 2023, BASF introduced the development of a new bio-based nylon resin called PA 6.10 CF, made from renewable resources and reinforced with carbon fiber for added strength and stiffness.

- In October 2022, Evco Plastics proposed expanding its manufacturing capacity in the United States with USD 11 million. Currently, the company operates 183 injection molding machines.

- In July 2022, ALPLA invested USD 850,000 in India for a mold shop. The mold shop in India is expected to be the company’s third such facility after Australia and Germany.

- In June 2022, ENGEL partnered with the ALPA Group, Brink, and IPB p, printing. It is expected to enable recycled material processing with a newly developed ENGEL e-speed injection molding machine with a powerful injection unit.

- In March 2022, Che Hsong Holdings Ltd. Signed a strategic cooperation agreement with Chiers, an electric car manufacturer. It has obtained several purchase orders for injection molding machine equipment from the company.

- In January 2022, Haitain entered into a joint venture with HCMC University of Technology and Education to operate the laboratory. The lab has dedicated areas for training, mold repair, and practical operations and is equipped with injection molding machines and robots.

- The more constant and efficient sequences of machines set the latest standard. They are known to be quicker than hydraulic machines, which employ accumulators for injection gestures to manufacture caps.

- Yizumi-HPM Corp., a part of the Yizumi Group and a dominating maker of high-quality injection molding machinery from 65 to 4400 tons, declares the launch of three (3) latest sequences of injection molding machines and the premiere of Yizumi-HPM full line of linear robots.

DETAILED SEGMENTATION OF THE GLOBAL INJECTION MOLDING MARKET INCLUDED IN THIS REPORT

This research report on the global injection molding market has been segmented and sub-segmented based on type, machine, clamping force, and region.

By Type

- Plastics

- Rubber

- Metal

- Ceramic

- Others

By Machine

- Hydraulic

- All-electric

- Hybrid

By Clamping Force

- 0-200 Ton Force

- 201-500 Ton Force

- Above 500 Ton Force

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]