Global Industrial Dust Collector Market Size, Share, Trends, & Growth Forecast Report - Segmented By Product Type (Bag house Dust Collectors, Wet Scrubber Dust Collectors, Cyclone Dust Collectors, Central Dust Collectors, Others), Mechanism (Dry, Wet), By Mobility (Portable, Fixed), Application (Food & Beverage, Pharmaceutical, Energy & Power, Steel, Cement, Mining, Others), & Region - Industry Forecast From 2024 to 2032

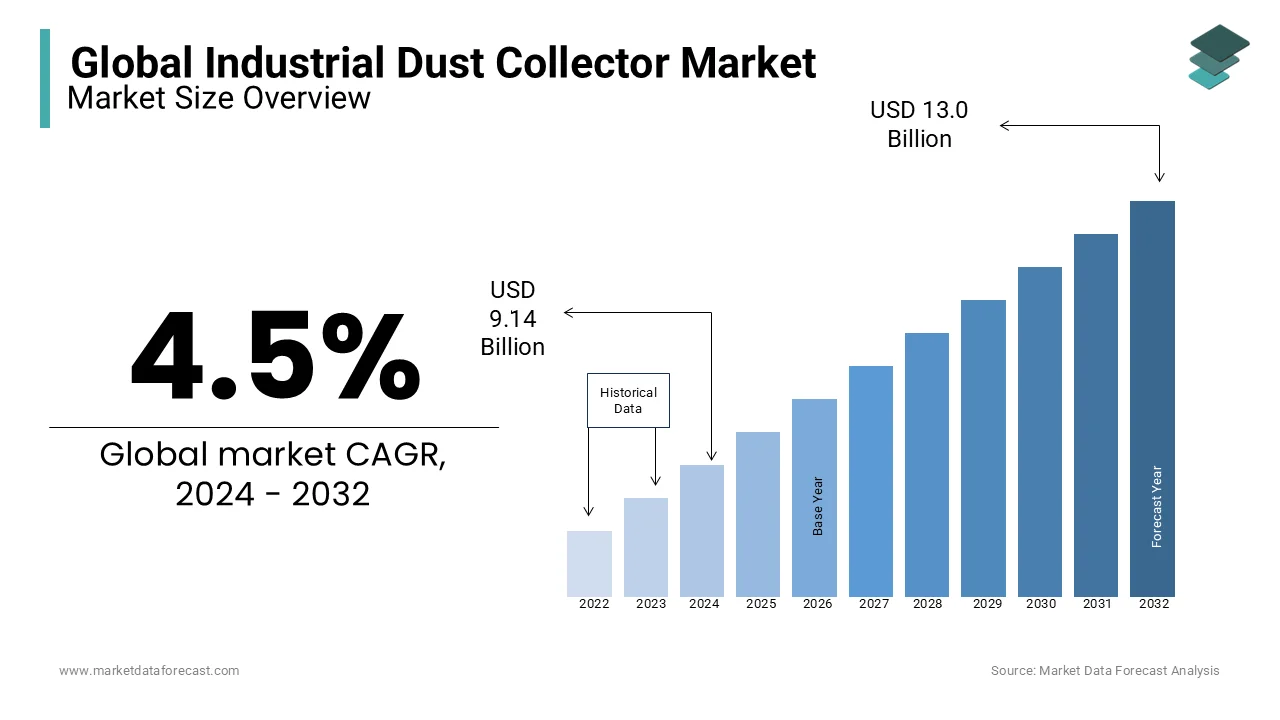

Global Industrial Dust Collector Market Size (2024 to 2032)

The global industrial dust collector market was worth USD 8.75 billion in 2023. The global market is predicted to reach USD 9.14 billion in 2024 and USD 13.0 billion by 2032, growing at a CAGR of 4.5% during the forecast period.

An industrial dust collector is equipment that is used in plants, factories, warehouses, and other industries. This equipment is used to collect dust from the industrial environment and also controls the air quality by removing any harmful matter and fumes from gases that may arise during a manufacturing process, resulting in a safer environment for workers and employees.

A dust collection system's basic components include a blower, dust filter, cleaning system, receptacle, ductwork, and a means of collecting pollutants. An industrial dust collector works by moving particles through a fan system to remove air pollutants from the workplace. The movement of an air stream is accelerated by the force generated by a fan in order to construct a setup that collects dust and harmful gases from the environment. The forces of centrifugal force, inertial force, and gravity are used to separate harmful gases and dust particles. The blower draws air from the location into the filter, which filters out particulates. The air-cleaning component is the dust filter. When air pollutants and dust particles pass through the system and are separated from the filter, they fall into a container known as hover for collection.

MARKET DRIVERS

The growing demand for food safety in the food and beverage industries, as well as the use of dust collectors to remove air pollutants that are harmful to workers and employees, are driving the market for industrial dust collectors.

Rapid industrialization and investments are also contributing to the growth of the market. The various advantages of industrial dust collectors and strict government safety regulations have made industries adopt them, which makes them a popular choice in the market. Advantages include increased manufacturing efficiencies; reduced worker exposure to harmful substances; adaptability in a variety of industries; and the ability to change the filter quickly and easily.

MARKET RESTRAINTS

Since most dust collectors use fabric filters, they require frequent filter cleaning, which can cause high maintenance costs since heavy dust loads require frequent filter cleaning. Most filters are cleaned by injecting high-pressure air into the filter, which causes the filter to expand as a result of the air pressure. Due to this, it becomes necessary to clean the filter on a more regular basis. As a result, the growth of the market is constrained by this key factor.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

4.5% |

|

Segments Covered |

By Product Type, Mechanism, Mobility, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

PARKER HANNIFIN CORP, Oneida Air Systems, FLSmidth, Donaldson Company, Inc., American Air Filter Company, Inc., 3M, Nederman, Camfil APC, CLARCOR Industrial Air, Industrial Vacuum Equipment Corporation, and Others. |

SEGMENTAL ANALYSIS

Global Industrial Dust Collector Market Analysis By Product Type

In this product type segment, Baghouse Dust Collectors are leading and are also expected to grow at a higher CAGR during the forecasted period. Baghouse Dust Collectors are extremely adaptable and can be designed for almost any dust-producing application by varying bag size and type. When compared to other types of dust collectors, these are very efficient and can handle any harsh applications in the industry.

Global Industrial Dust Collector Market Analysis By Mechanism

Dry is leading the mechanism segment and is expected to grow at a high rate during the forecasted period. The market is driven due to dry dust particle issues in the food and beverage and cement industries. Combustible dust causes explosions and fires in the food and beverage industry. As a result, installing industrial dust collectors in the food and beverage industry not only improves air quality but also protects workers from getting lung diseases.

Global Industrial Dust Collector Market Analysis By Mobility

Fixed segment holds the largest market share in 2021 as many industries require large dust collectors. The portable segment is expected to grow at a high rate during the forecasted period. Portable dust collectors are economical as compared to fixed dust collectors. When in an industry, the dust generation is not fixed in one place and there are many machines working on a shop floor that is being operated for a very short period of time, a portable dust collector with a flexible arm arrangement will be a cost-effective way compared to a fixed or centralized dust collection system. Also, the filters require no installation or setup cost and very low maintenance cost. These benefits are driving the portable segment.

Global Industrial Dust Collector Market Analysis By Application

Food & Beverage is leading the application segment and is expected to grow at a high rate during the forecasted period. The market is driven by the strict safety policies and regulations of the government globally. In the food industry, dust particles are the major issue that settle on contaminated products before the packaging process, and thus the use of dust collectors plays a major role.

REGIONAL ANALYSIS

North America holds the largest market share in 2021 as it is a developed country and has adopted various advanced technologies and equipment. Asia pacific is expected to grow at the highest rate during the forecasted period. This growth will be driven by the rapid investment and industrialization in this region. Strict government policies and an increase in safety, mainly in food and beverage companies, are driving the region forward. China is the world's largest producer of cement, followed by India, and these government policies will have an impact on these industries, which will drive the industrial dust collection market.

KEY MARKET PLAYERS

Major Key Players in the Global Industrial Dust Collector Market are PARKER HANNIFIN CORP, Oneida Air Systems, FLSmidth, Donaldson Company, Inc, American Air Filter Company, Inc, 3M, Nederman, Camfil APC, CLARCOR Industrial Air, Industrial Vacuum Equipment Corporation, and others.

RECENT HAPPENINGS IN THE MARKET

- In April 2022, Parker Hannifin Corp. launched a pleated baghouse filter for customers which collects dust in high-temperature applications. It is designed to remove bags and cages, significantly decreasing installation and removal costs.

- In October 2020, Donaldson Company, Inc. has announced to launch of a Donaldson Torit Rugged Pleat baghouse industrial dust collector. It is intended to collect heavy, abrasive dust generated by woodworking, mining, grain processing, and other industries.

- In May 2022, Eitrium announced the acquisition of Ilmeg Products AB, a Swedish manufacturer of dust collectors, primarily for the mining industry to increase its product and strengthen its position in the market.

DETAILED SEGMENTATION OF THE GLOBAL INDUSTRIAL DUST COLLECTOR MARKET INCLUDED IN THIS REPORT

This research report on the global industrial dust collector market has been segmented and sub-segmented based on product type, mechanism, mobility application, and region.

By Product Type

- Bag House Dust Collectors

- Wet Scrubber Dust Collectors

- Cyclone Dust Collectors

- Central Dust Collectors

- Others

By Mechanism

- Dry

- Wet

By Mobility

- Portable

- Fixed

By Application

- Food & Beverage

- Pharmaceutical

- Energy & Power

- Steel

- Cement

- Mining

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- The Middle East and Africa

Frequently Asked Questions

What are the key factors driving the growth of the Industrial Dust Collector Market globally?

The primary drivers include rising industrialization in emerging economies, stringent environmental regulations aimed at reducing air pollution, increasing awareness of workplace safety, and the growing demand for energy-efficient and high-performance dust collection systems.

What are the major types of industrial dust collectors available in the market?

The major types include baghouse dust collectors, cyclone dust collectors, cartridge dust collectors, wet scrubbers, and electrostatic precipitators. Each type has its specific applications depending on the industry and the type of dust to be collected.

How is technology impacting the Industrial Dust Collector Market?

Technological advancements are leading to the development of more efficient, energy-saving, and automated dust collection systems. Innovations such as IoT-enabled dust collectors, advanced filtration media, and smart sensors are enhancing the operational efficiency and reliability of these systems.

How do environmental regulations influence the Industrial Dust Collector Market?

Environmental regulations, especially those targeting air quality and emissions control, significantly influence the market. Regulations such as the Clean Air Act in the U.S. and similar frameworks in the EU require industries to limit particulate emissions, driving the demand for effective dust collection systems.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]