Global Heavy Duty Connector Market Size, Share, Trends, & Growth Forecast Report – Segmented By Component (Hoods and Housings, Insert and Contact and Accessories), Material (Metal and Plastic), Termination Style (Crimp, Screw and Others), Application (Manufacturing, Power, Rail, Oil, And Gas, Construction and Others) & Region - Industry Forecast From 2024 to 2032

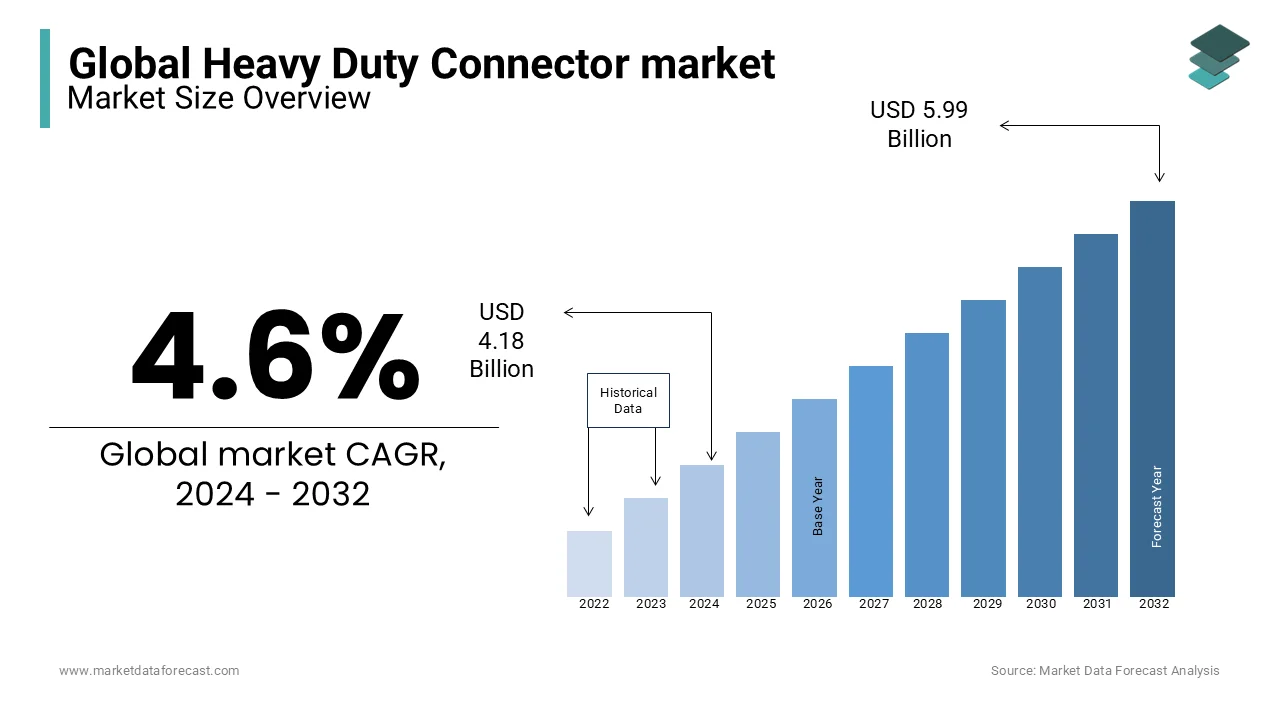

Global Heavy Duty Connector Market Size (2024 to 2032)

The global heavy duty connector market was worth USD 4.0 billion in 2023. The global market is expected to grow at a CAGR of 4.6% from 2024 to 2032 and the global market size is anticipated to be valued at USD 5.99 billion by 2032 from USD 4.18 billion in 2024.

Heavy-duty connectors are electrical connectors that are specifically constructed for use in major industrial applications. They are also known as multiple connectors or industrial connections. In environments where there are challenging conditions, including intense heat, humidity, vibration, and mechanical stress, they are used to provide secure and stable electrical connections. Heavy-duty connectors are often larger and more reliable than standard connectors. Due to their durable construction, strong materials, and effective sealing mechanisms, they offer protection against dust, water, chemicals, and other impurities. These connectors can tolerate high currents and voltages, making them suitable for power transmission applications.

MARKET DRIVERS

The growing industrial automation is propelling the growth of the global heavy-duty connector market.

Many industries are turning to automation, and they need strong and efficient electrical connections. Heavy-duty connectors are specially designed to provide secure and long-lasting connections for automation equipment like robots, control systems, and sensors. Due to this, the demand for heavy-duty connectors is increasing. Heavy-duty connectors reduce the chances of electrical failures or accidents, which can be expensive as well as harmful. Because they have a major focus on operational safety and seek to minimize downtime caused by inappropriate connections, these connectors are highly regarded by industries. By using heavy-duty connectors, they can maintain a dependable and safe electrical system while reducing the risks associated with faulty connections. These advantages of heavy-duty connectors fuel the market’s growth rate.

The demand for high-power applications drives the requirements for the use of heavy-duty connections that can carry more electrical current. These connectors improve the operation of machinery such as motors, drives, and power distribution systems and enable the effective transmission of power. As industries such as renewable energy, electric vehicles, and smart infrastructure are growing, they need strong and reliable electrical connections, which creates an opportunity for heavy-duty connector manufacturers to meet their unique requirements and become important suppliers in these rapidly growing industries. As the heavy-connectors technology continued to advance, with improvements in materials and enhanced sealing capabilities, new opportunities arose for the development of more efficient and compact heavy-duty connectors. Manufacturers can take advantage of these advancements to create innovative solutions that satisfy constantly evolving customer requirements and specifications.

MARKET RESTRAINTS

Heavy-duty connectors can be more costly than standard connectors because of their unique design, materials, and features. This higher cost restricts certain industries, especially those with limited budgets or markets that prioritize cost-effective solutions, which causes restricted demand for the heavy-duty connector market. Installing and maintaining heavy-duty connectors can be more complex compared to standard connectors because of their modular and customizable design. This complexity can result in longer installation times, and more work can be required, which can negatively impact overall operational effectiveness.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

4.6% |

|

Segments Covered |

By Component, Material, Termination Style, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

Toyota Industries (Japan), KION Group (Germany), Hyster-Yale Material Handling (US), Oshkosh (US), Linamar (Canada), Konecranes (Finland), Cargotec (Finland), Terex (US), Tadano (Japan), Liebherr (Switzerland), Manitowoc (US), Ingersoll Rand (Ireland), Mammoet (Netherlands), ZPMC (China), KITO (Japan), XCMG (China), Zoomlion (China), and Columbus McKinnon (US) and Others. |

SEGMENTAL ANALYSIS

Global Heavy Duty Connector Market Analysis By Component

Based on components, the insert and contact segment had the leading share of the global market in 2023 and is expected to continue the domination during the forecast period. Contacts are the conductors that create the electrical connection between the connectors, and inserts are the center of the connector, which provide the structure and arrangement for contracts.

On the other hand, the hoods and housing segment is deemed to have significant growth in the heavy duty connector market during the forecast period.

Global Heavy Duty Connector Market Analysis By Material

Based on material, the metal segment is anticipated to dominate the heavy-duty connector market, accounting for the largest share during the forecast period as heavy-duty connectors made from metals are suitable for applications including industrial machinery, automation systems, and outdoor installations where durability and reliability are essential.

The plastic segment is deemed to have significant growth in the heavy-duty connector market.

Global Heavy Duty Connector Market Analysis By Termination Style

Based on the termination style, the crimp segment is estimated to capture the major share of the worldwide market during the forecast period. As crimp termination is known for having an effective mechanical and electrical connection, it is suitable for applications that demand high conductivity and vibration resistance.

Global Heavy Duty Connector Market Analysis By Application

Based on application, the manufacturing segment is estimated to dominate the market with the largest share of the global market during the forecast period. Heavy-duty connectors find extensive use in manufacturing industries for machinery and equipment connections.

The power segment is expected to grow at the fastest CAGR in the global market during the forecast period. To maintain reliable and secure electrical connections, heavy-duty connectors are utilized in power plants, substations, renewable energy systems, and other electrical systems.

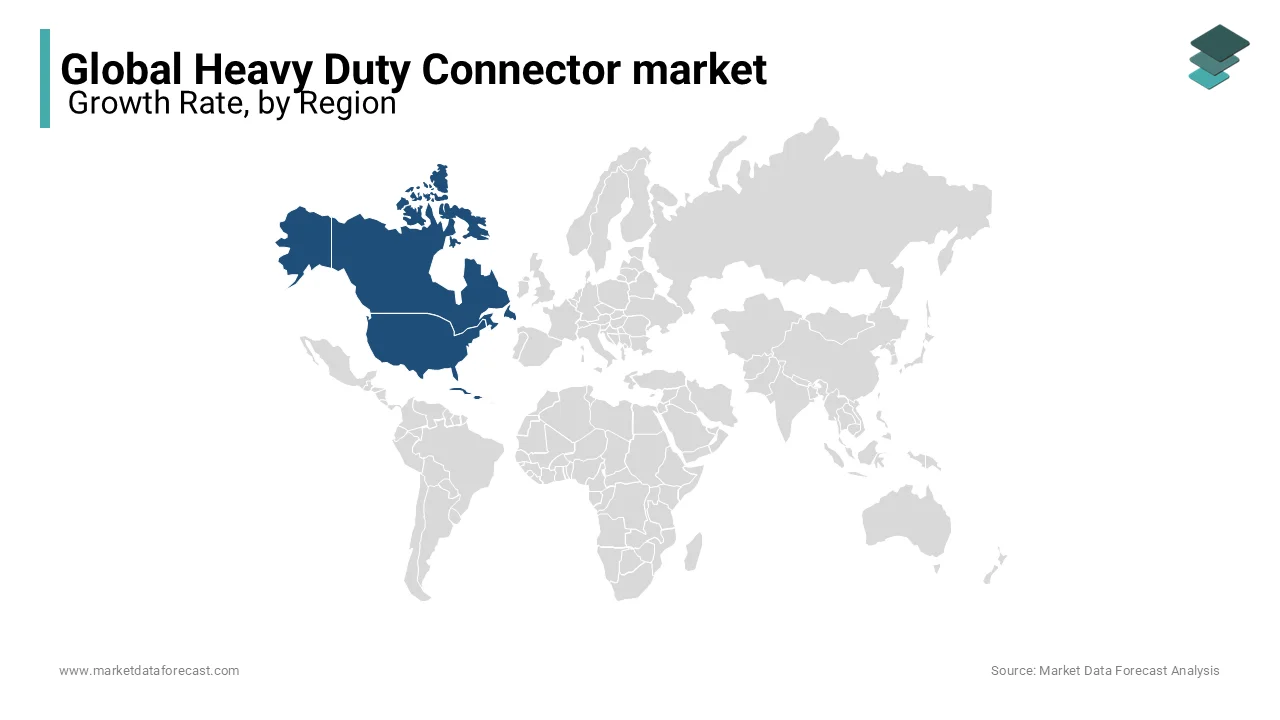

REGIONAL ANALYSIS

North America is anticipated to dominate the heavy-duty connector market globally, with the largest market share during the forecast period owing to rapid industrialization, including automotive, manufacturing, aerospace, and energy industries, in which the demand for heavy-duty connectors is very high. The Asia-Pacific region is expected to grow at the fastest CAGR, leading to significant market share.

KEY MARKET PLAYERS

Companies playing a leading role in the global heavy duty connector market include Amphenol Sine Systems, Bulgin, China Utility Electrical Co. Ltd., Degson Electronics Co., Ltd., Harting Technology Group, Indo Electricals, ITT Cannon, Lapp Holding AG, Molex LLC, Ningbo Oukerui Connector Co, Ltd., ODU GmbH & Co. KG., Phoenix Contact, Schaltbau GmbH, Smiths Interconnect, TE Connectivity Ltd., Walther Electric, Inc., Weald Electronics Ltd., Weidmuller Interface GmbH & Co. KG and Weisscam GmbH.

RECENT HAPPENINGS IN THE MARKET

- In 2021, A leader in networking and sensors, TE Connectivity (TE), recently introduced the HDSCS connector.

- In 2022, New heavy-duty connector types were being developed and made accessible by industries for use in a variety of applications, including space-grade connectors.

DETAILED SEGMENTATION OF THE GLOBAL HEAVY DUTY CONNECTOR MARKET INCLUDED IN THIS REPORT

This research report on the global heavy duty connector market has been segmented and sub-segmented based on component, material, termination style, application and region.

By Component

- Hoods and Housings

- Insert and Contact

- Accessories

By Material

- Metal

- Plastic

By Termination Style

- Crimp

- Screw

- Others

By Application

- Manufacturing

- Power

- Rail

- Oil and Gas

- Construction

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Frequently Asked Questions

What are the key applications of heavy-duty connectors globally?

Globally, heavy-duty connectors are used in a wide range of applications including automation, robotics, energy & power, automotive manufacturing, and industrial machinery. These connectors are designed to ensure secure and robust electrical and signal connections in harsh environments such as construction sites, factories, and railways.

What trends are driving the growth of the Heavy-Duty Connector market?

Key trends include the rise of Industry 4.0 and smart manufacturing, which demand more reliable and high-performance connectivity solutions. The increasing need for miniaturization, lightweight connectors, and the growing adoption of renewable energy sources like wind and solar, which require durable connectors in tough conditions, are also driving market growth.

How is the adoption of renewable energy influencing the Heavy-Duty Connector market?

The rise in renewable energy projects, especially in solar and wind energy, is positively impacting the heavy-duty connector market. These industries require robust connectors that can withstand extreme weather conditions, high temperatures, and other harsh environments, driving demand for reliable and durable connectivity solutions.

What is the future outlook for the Heavy-Duty Connector market globally?

The future outlook for the heavy-duty connector market is positive, with continued growth expected across various industries. Increasing investments in infrastructure, renewable energy, electric vehicles, and industrial automation will be key drivers. Technological innovations and the push towards more sustainable and efficient manufacturing processes will also contribute to the market’s expansion over the next decade.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]