Europe Rubber Hose Market Research Report – Segmented By Product Type ( Natural Latex (Rubber), Synthetic Rubber ) Media ( Water, Oil ) Pressure Rating (Low Pressure, High Pressure ) Application (Industrial, Automotive ) & Country (UK, France, Spain, Germany, Italy, Russia, Sweden, Denmark, Switzerland, Netherlands, Turkey, Czech Republic & Rest of EU) - Industry Analysis on Size, Share, Trends & Growth Forecast (2025 to 2033)

Europe Rubber Hose Market Size

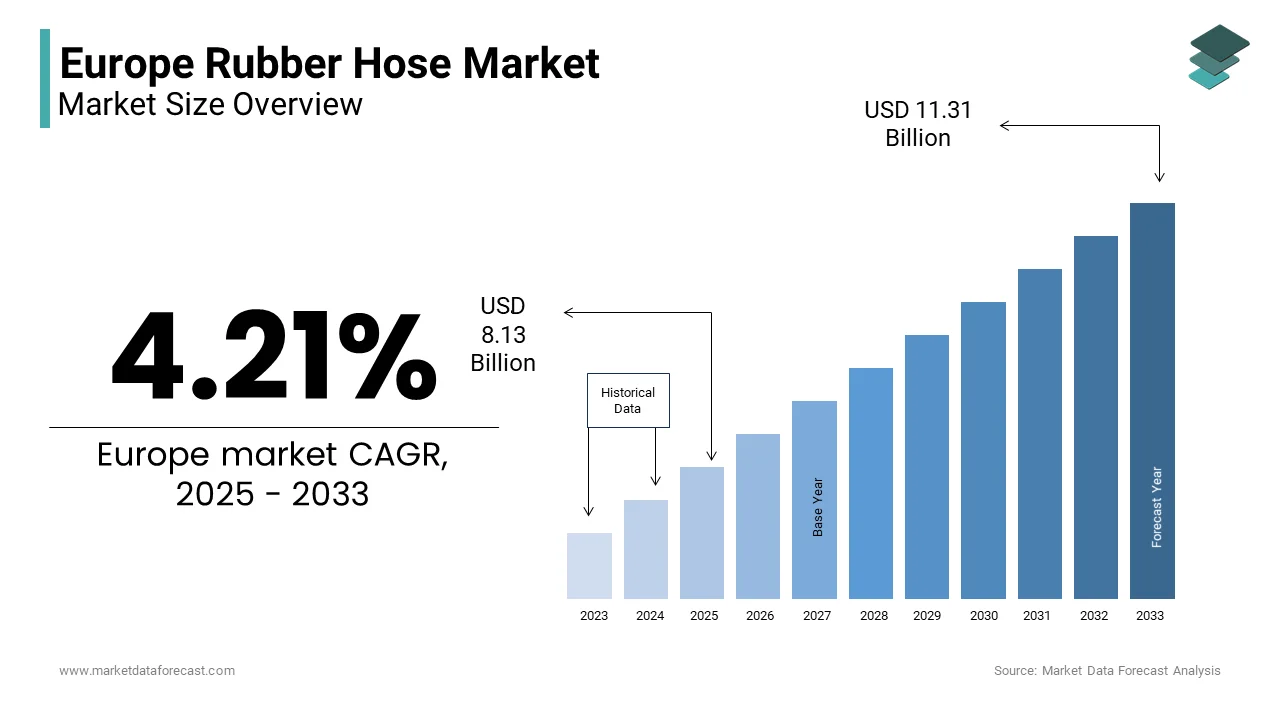

The europe rubber hose market Size was valued at USD 7.8 billion in 2024. The europe rubber hose market size is expected to have 4.21% CAGR from 2025 to 2033 and be worth USD 11.31 billion by 2033 from USD 8.13 billion in 2025.

Rubber hoses are essential components in numerous applications which is providing flexibility, durability, and resistance to various environmental factors such as temperature, pressure, and chemicals. The market has experienced significant growth driven by the increasing demand for high-performance hoses that can withstand rigorous operating conditions.

The market includes many different kinds of rubber hoses covring hydraulic hoses, industrial hoses, and specialty hoses, each designed for specific applications. The growing emphasis on sustainability and the circular economy is also propelling the demand for eco-friendly rubber hoses, particularly those made from recycled materials. As industries keep changing and improving, the need for high-quality rubber hoses is expected to grow, helping this market expand a lot in the next few years.

MARKET DRIVERS

Increasing Demand from the Automotive Sector

The increasing demand from the automotive sector serves as a primary driver for the Europe Rubber Hose Market. As the automotive industry persistently growing, the demand for high-quality rubber hoses for things like fuel delivery, cooling systems, and air conditioning has become very important. As per the European Automobile Manufacturers Association, approximately 15 million new vehicles were registered in Europe in 2022, reflecting a robust automotive market that directly correlates with the demand for rubber hoses. This trend is becoming even more important as more electric vehicles (EVs) hit the market, needing special rubber hoses for cooling batteries and other parts. With manufacturers creating new and improved hoses designed for automotive use, the demand is likely to stay high, helping this part of the market grow steadily over time.

Growth in Industrial Applications

The growth in industrial applications is another significant driver of the Europe Rubber Hose Market. Various industries including construction, mining, and manufacturing, rely heavily on rubber hoses for transporting fluids, gases, and materials. The versatility and durability of rubber hoses make them ideal for a wide range of applications, from hydraulic systems to pneumatic tools. The relevance of this factor is showcased by the rising demand for high-performance hoses that can withstand extreme conditions, such as high pressure and temperature fluctuations. As industries grow and upgrade their operations, the need for dependable rubber hoses is likely to increase. Companies that create new and specialized rubber hose solutions for industrial use have a good chance to take advantage of this rising demand and stand out in the competitive market.

MARKET RESTRAINTS

Fluctuating Raw Material Prices

The fluctuating prices of raw materials used in the production of rubber hoses is one of the primary restraints affecting the Europe Rubber Hose Market. The prices of key materials such as natural rubber and synthetic rubber have been subject to volatility due to global supply chain disruptions, geopolitical tensions, and changes in demand. The industry analysts suggest that the cost of natural rubber has increased by approximately 20% over the past year is impacting the overall production costs for rubber hoses. These elevated raw material costs can pose challenges for manufacturers, particularly smaller companies with limited resources. As a result, some manufacturers may be hesitant to invest in advanced rubber hose technologies, opting instead for more cost-effective alternatives. This reluctance can hinder the overall growth of the market, as the adoption of innovative rubber hose solutions may be slower than anticipated.

Stringent Environmental Regulations

Another significant restraint in the Europe Rubber Hose Market is The strict environmental regulations governing the production and use of rubber products is another grave problem for the Europe Rubber Hose Market. The rubber industry is subject to various regulations aimed at reducing environmental impact, particularly concerning emissions and waste management. Compliance with these regulations often requires extensive testing, certification, and documentation, which can be time-consuming and costly for manufacturers. The European Chemicals Agency stresses that compliance with regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) can be complex and burdensome for rubber hose manufacturers. These regulatory challenges can hinder the growth of the rubber hose market, as manufacturers may face delays in product approvals and increased costs associated with compliance. Additionally, the growing emphasis on sustainability and the shift towards eco-friendly materials may further limit the market potential for traditional rubber hoses.

MARKET OPPORTUNITIES

Expansion of Recycling Initiatives

The expansion of recycling initiatives presents a significant opportunity for the Europe Rubber Hose Market. As sustainability becomes a central focus for industries worldwide, the recycling of rubber materials has gained prominence due to its environmental benefits and economic viability. The recycling of rubber hoses can reduce waste and lower production costs, making it a highly sustainable option. As per the European Commission, the circular economy action plan aims to increase recycling rates across various sectors, including rubber, which will drive demand for recycled materials. The increasing emphasis on circular economy principles is driving the demand for recycled rubber hoses, which can be produced from waste materials. This trend is particularly relevant in the automotive and industrial sectors, where manufacturers are seeking to reduce their carbon footprint and comply with stringent environmental regulations. Companies that pays attention on developing high-quality recycled rubber hoses can capitalize on this growing market opportunity, positioning themselves as leaders in the sustainable materials sector.

Technological Advancements in Manufacturing Processes

Technological advancements in manufacturing processes present another major opportunity for the Europe Rubber Hose Market. Innovations in production techniques, such as improved extrusion methods and the development of advanced rubber compounds, are enhancing the efficiency and quality of rubber hose manufacturing. These advancements enable manufacturers to produce hoses that offer superior performance, durability, and resistance to environmental factors. As makers put more effort into developing advanced rubber hose technologies, the need for new and improved solutions is expected to grow. Businesses that use these innovations to boost their production can grab a bigger piece of the expanding market and set themselves up for long-term success in the competitive rubber hose industry.

MARKET CHALLENGES

Supply Chain Disruptions

One major problem for the Europe Rubber Hose Market is weak and easily disrupted supply chains. Making rubber hoses depends on many suppliers providing key materials like natural rubber and synthetic polymers. Events like the COVID-19 pandemic and global conflicts have exposed how easily these supply chains can break down, causing delays and higher costs. Experts say these issues have led to a 20% rise in the time it takes to deliver rubber products, including hoses. These delays make it harder for manufacturers to stay on schedule and meet customer demand, which can hurt sales and reduce their share of the market. On top of that, changing prices and shortages of raw materials make it even tougher for companies to get what they need to produce rubber hoses.

Competition from Alternative Materials

The competition from alternative materials presents a significant challenge for the Europe Rubber Hose Market. As industries seek to innovate and improve performance, various materials such as thermoplastic elastomers (TPEs) and composites are emerging as viable alternatives to traditional rubber hoses. These alternatives may offer unique advantages, such as lower weight, enhanced flexibility, and improved resistance to chemicals and temperature extremes. According to market research, approximately 30% of manufacturers are exploring alternative materials to reduce costs and improve product performance. This competitive landscape can make it difficult for rubber hose manufacturers to maintain market share, particularly as companies seek innovative solutions to enhance their products. Additionally, investing in research and development to enhance the performance of rubber hoses can help manufacturers stay competitive in a rapidly evolving market.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 to 2033 |

|

Base Year |

2024 |

|

Forecast Period |

2025 to 2033 |

|

CAGR |

4.21 % |

|

Segments Covered |

By Product Type, Media, Pressure Rating, Application and Country. |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis; DROC, PESTLE Analysis, Porter's Five Forces Analysis, Competitive Landscape, Analyst Overview of Investment Opportunities |

|

Country Covered |

UK, Germany, Italy, France, Spain, Sweden, Denmark, Poland,Switzerland, Netherlands, Rest of Europe. |

|

Market Leader Profiled |

Parker Hannifin Corp, Continental AG, Tricoflex SAS, Trelleborg Group, Manuli Hydraulics, Danfoss. |

SEGMENT ANALYSIS

By Product Type Insights

The natural latex (rubber) segment of the Europe Rubber Hose Market was the biggest product type and captured 52.1% of the total market share in 2024 owing to the excellent elasticity, flexibility, and resilience offered by natural rubber, making it an ideal choice for various applications, including automotive, industrial, and agricultural hoses. These natural ones are favoured for their ability to withstand high pressures and temperatures and is providing reliable performance in demanding environments. This segment is becoming more important because more customers are looking for high-quality rubber hoses that can meet strict performance requirements. The industry estimates indicated that the demand for natural rubber hoses is anticipated to grow at a rate of 5% over the next five years which is driven by the rising production of vehicles and the need for effective hose solutions. As manufacturers keep improving and making new natural rubber products, this part of the market is likely to stay an important factor in helping the rubber hose industry grow.

The synthetic rubber segment is the fastest-growing category within the Europe Rubber Hose Market, with an estimated CAGR of 6.2% over the forecast period because of the increasing demand for synthetic rubber hoses in various applications particularly in the automotive and industrial sectors. It offers superior resistance to chemicals, heat, and aging compared to natural rubber is making it a preferred choice for many manufacturers. This part is reinforced by its potential to serve the growing consumer preference for durable and high-performance hoses. Because industries continue to evolve and demand more advanced materials, the need for synthetic rubber hoses is expected to rise. Companies that create new and specialized types of synthetic rubber for specific uses can take advantage of this growing market and improve their chances of doing well in the competitive rubber hose industry.

By Media Insights

The water media segment remained the best performing category in the Europe Rubber Hose Market by accounting for 41.5% of the total market in 2024. The extensive use of rubber hoses for water transportation in various applications, including irrigation, construction, and municipal water supply is adding to the support of this segment. These are designed for water applications are favored for their flexibility, durability, and resistance to abrasion, making them ideal for handling water in diverse environments. The segment is made significant by the surging investments in water infrastructure and irrigation systems across Europe. The industries keep on investing in modernizing their water supply systems, hence, the demand for high-quality rubber hoses for water applications is believed to remain strong which is positioning this segment for sustained growth.

The oil media segment is experiencing a sudden rise in the Europe Rubber Hose Market with a projected CAGR of 6.5% from 2023 to 2028. This growth can be attributed to the increasing demand for rubber hoses in the oil and gas industry, where they are used for transporting crude oil, refined products, and other petroleum-based fluids. These rubber hoses designed for oil applications are engineered to withstand high pressures and temperatures, ensuring safe and efficient transportation. The value of this segment is made by its ability to support the growing energy demands while ensuring efficient resource utilization. As the oil and gas industry continues to invest in infrastructure and exploration activities, the demand for rubber hoses in oil applications is expected to rise. The players attention in on developing innovative rubber hose solutions tailored for the oil and gas sector can capitalize on this growing market opportunity, positioning themselves for long-term success in the energy industry.

By Pressure Rating Insights

The low-pressure segment dominated the Europe Rubber Hose Market by accounting for 55.4% of the total market. This is primarily due to the extensive use of low-pressure rubber hoses in various applications including water supply, irrigation, and general industrial use. Low-pressure hoses are favoured for their flexibility and ease of handling is making them suitable for a wide range of tasks. The relevance of this category is showcased by the increasing demand for reliable and cost-effective solutions in various industries. As manufacturers continue to innovate and develop high-quality low-pressure hoses, this segment is expected to remain a key driver of growth in the rubber hose market.

The high-pressure segment is seeing swift development within the Europe Rubber Hose Market, with a calculated CAGR of 6.2% during the forecast period. This progress can be linked to the elevating demand for high-pressure rubber hoses in applications such as hydraulic systems, oil and gas transportation, and industrial machinery. High-pressure hoses are engineered to withstand extreme conditions, providing reliable performance in demanding environments. The section illustrated by its feature to cater to the growing consumer preference for durable and high-performance hoses. The industries remain on course to evolve and demand more advanced materials, the need for high-pressure rubber hoses is expected to rise. Organization that emphasize on developing innovative high-pressure rubber hose solutions tailored for specific applications can capitalize on this growing market opportunity is positioning themselves for success in the competitive rubber hose landscape.

By Application Insights

The industrial application segment registered the largest share in the Europe Rubber Hose Market under this category and captured 51.3% of the total market in 2024 owing to the extensive use of rubber hoses in various industrial applications, including manufacturing, construction, and mining. Rubber hoses are essential for transporting fluids, gases, and materials in industrial settings, providing flexibility and durability in demanding environments. This part is emphasized by the increasing investments in industrial infrastructure and the growing demand for efficient material handling solutions. The industry data shows that the demand for rubber hoses in industrial applications is projected to spike notably over the next five years which is driven by the rising production of industrial equipment and the need for effective transportation solutions. The producers continue to innovate and develop high-quality rubber hoses for industrial applications, this segment is expected to remain a key driver of growth in the rubber hose market.

The automotive application segment is predicted to witness the highest CAGR of 6.5% from 2025 to 2033 due to the surging demand for rubber hoses in automotive applications, particularly for fuel delivery, coolant systems, and air conditioning. Rubber hoses are critical components in vehicles, ensuring the efficient transportation of fluids and gases. The relevance of this segment is demonstrated by its ability to enhance vehicle performance and safety. As the automotive industry continues to evolve, with a growing emphasis on electric vehicles and advanced technologies, the demand for high-quality rubber hoses is expected to rise. The attention of players is on developing innovative rubber hose solutions tailored for automotive applications can capitalize on this growing market opportunity, positioning themselves for success in the competitive automotive landscape.

Country Level Analysis

Germany spearheaded the Europe Rubber Hose Market and possessed 28.2% of the total market share in 2024. This influence is greatly due to its robust industrial sector, which includes significant applications of rubber hoses in automotive, manufacturing, and construction. There is a strong focus on innovation and sustainability, German manufacturers are increasingly adopting advanced rubber hose solutions to meet the growing demand for effective and durable products. The presence of major manufacturers and suppliers in Germany further bolsters the market's growth, as these companies seek to enhance performance and sustainability through effective rubber hose solutions.

France’s rubber hose market is also considered to be in the mature stage although it shows signs of innovation-driven demand. The growth rate is moderate, supported by technological advancements in hose durability and performance, especially for specialized applications. The level of demand is medium to high, stemming from sectors such as automotive (Renault, PSA Group), aerospace (Airbus), and food processing industries. France benefits from a well-established customer base composed of large industrial players and automotive suppliers who rely on both OEM and aftermarket hose solutions. The French market is expected to grow at a CAGR of 4.1% in the coming years. The French government has also been proactive in promoting environmental initiatives, which further supports the growth of the rubber hose market. As industries invest in modernizing their processes, the demand for rubber hoses is anticipated to rise, positioning France as a key player in the European rubber hose landscape.

The United Kingdom’s rubber hose market is in a mature stage but shows resilience thanks to its diversified industrial sectors. he intensity of demand is medium and is largely influenced by infrastructure activities and energy projects. The customer base is diverse but somewhat smaller compared to Germany or France, with a mixture of industrial OEMs, construction firms, and distributors sustaining the market. The UK’s diverse industrial landscape, combined with a growing awareness of the benefits of rubber hoses, positions it as a vital market within the European rubber hose sector.

Italy is positioned in a late growth to early maturity stage within the Europe Rubber Hose Market. The country is experiencing a moderate growth rate, slightly higher than that of more mature markets like France or the UK. This is primarily due to strong domestic manufacturing, automotive component production, and a robust hydraulic machinery sector. A recent study indicated that around 65% of Italian manufacturers are investing in modern rubber hose technologies to improve their production capabilities. The demand level is moderate, with additional support from sectors like food processing and agriculture. The customer base is steadily expanding, driven by mid-sized industrial enterprises and Italy’s strong connection to Stellantis (Fiat) and other automotive and machinery suppliers.

Spain is currently in a growth stage within the Europe Rubber Hose Market, experiencing a relatively strong growth rate compared to other Western European nations. This upward trend is largely fueled by the country’s ongoing industrial expansion, increased construction activity, and the steady rise of its automotive sector, supported by manufacturing facilities from companies like SEAT and Renault. The demand for rubber hoses is moderate but climbing, driven by infrastructure upgrades, agricultural modernization, and expanding manufacturing operations. Spain’s customer base is broadening, with more businesses investing in industrial equipment and components, positioning the country as an emerging hotspot in the European rubber hose landscape.

KEY MARKET PLAYERS

Key players operating in the Europe Rubber Hose Market profiled in this report are Parker Hannifin Corp, Continental AG, Tricoflex SAS, Trelleborg Group, Manuli Hydraulics, Danfoss, KURIYAMA EUROPE COÖPERATIEF U.A. (Subsidiary of Kuriyama Holdings Corp.), Gates Corporation, WITZENMANN, Semperit AG Holdings, Schauenburg Hose Technology Group.

MARKET SEGMENTATION

This research report on the Europe Rubber Hose Market has been segmented and sub-segmented into the following categories.

By Product Type

- Natural Latex (Rubber)

- Synthetic Rubber

By Media

- Water

- Oil

By Pressure Rating

- Low Pressure

- High Pressure

By Application

- Industrial

- Automotive

By Country

- UK

- France

- Spain

- Germany

- Italy

- Russia

- Sweden

- Denmark

- Switzerland

- Netherlands

- Turkey

- Czech Republic

- Rest of Europe.

Frequently Asked Questions

Which industries are the primary consumers of rubber hoses in Europe?

The primary consumers include the industrial, commercial, municipal, automotive, and transportation sectors.

What role does the automotive industry play in the Europe rubber hose market?

The automotive industry is a significant consumer of rubber hoses, utilizing them in various vehicle systems, thereby contributing to market growth.

How are technological advancements impacting the rubber hose market in Europe?

Technological advancements are leading to the development of more durable and efficient rubber hoses, enhancing their performance across various applications.

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2000

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]