Global Corrosion Monitoring Market Size, Share, Trends & Growth Forecast Report – Segmented By Type (Intrusive And Non- Intrusive), Technique (Corrosion Coupons, Electrical Resistance, Linear Polarization Resistance, Galvanic, and Ultrasonic Thickness Measurement), End-Use Industry (Oil & Gas, Chemical, Manufacturing and Others) and Region (North America, Latin America, Europe, Asia Pacific, Middle East & Africa) - Industry Analysis (2024 to 2032)

Global Corrosion Monitoring Market Size (2024 to 2032)

The global Corrosion monitoring market size is expected to be worth USD 358.16 million in 2024 and USD 839.18 million by 2032, growing at a CAGR of approximately 11.2% during the forecast period from 2024 to 2032.

Current Scenario of the Global Corrosion Monitoring Market

The corrosion monitoring market is advancing at a steady pace. It is the equipment used to get information on the corrosion rate in a mill per year using a set of methods. The equipment will provide complete information regarding the corrosion rate online or offline. The surveillance helps prevent or take necessary measures to combat gradual weakening. There are many measures to combat corrosion, but eventually, rust tracking is highly important to identify the effect of corrosion and process effective procedures. Usually, companies do follow preventive measures for corrosion, but knowing the accurate results through equipment and taking the next step in protection is highly recommended to the companies. Corrosion tracking can check on the change frequently and evaluate the need to improve the preventive measure with the predicted results. The proper monitoring of the components will eventually increase the life expectancy of the unit. The detection of early warning signs of corrosion is very important as it causes a major threat in the end-user industries. For instance, corrosion poses a major threat to the oil and gas industry, where negligence will result in the loss of huge dollars and sometimes the lives of innocent individuals working there. Therefore, the purpose of this surveillance is to promote safety and improve the productivity of the company.

MARKET DRIVERS

The growing usage of corrosion monitoring in the oil and gas industry has been a key growth driver for the corrosion monitoring market.

The oil and gas industry has a significant application area for corrosion monitoring. Corrosion monitoring is a significant tool against premature degradation like safety and environmental problems. Corrosion can have price punishments owing to the loss in production, repairs, and unplanned substitutions of the systems and components. Escalating awareness about corrosion monitoring and failure related to corrosion is a significant driving factor for the expansion of the worldwide industry. The pipeline industry and refineries are among other elements promoting the development of the corrosion monitoring market. Energy consumption, the rise in manufacturing and exploration of crude oil, and increasing call from the downstream industry are predicted to push the call for corrosion monitoring systems in the coming future. Expansion in urbanization and employment of reinforced concrete structures in construction may also boost the worldwide corrosion monitoring industry in the near few years. Aging infrastructure in old businesses is boosting the consumption of corrosion monitoring goods and the rising expansion of oil refineries has led to an escalating call for monitoring equipment as it assists the companies to reduce their maintenance expenses, driving development in the industry. The expansion in the corrosion monitoring system is high owing to increasing calls from end-user businesses like power generation and Oil & Gas.

The rise in the deployment of Internet of Things (IoT) solutions in the oil and gas industry is contributing to the expansion of the corrosion monitoring market.

IoT is making an effective financial effect on oil and gas refineries and pipelines worldwide offering solutions for safety and performance worries in the type of pervasive sensing solutions. The risen use of wireless technology for corrosion monitoring is one of the major factors driving the market expansion. The corrosion monitoring system is a major part of so many businesses that help in raising productivity and reducing downtime. The checking of corrosion and volatility in factors like vibration, heat, and leak and oil analysis assists in getting to know the problems early. Online corrosion monitoring done with the help of wireless technologies adds extra ease and enables remote monitoring. These systems are more advantageous as they provide immediate data, constant coverage, and data of machines. Also, sensors are the major parts of corrosion monitoring systems. The sensor technology industry is integrating better and better developments to show optimum services. Latest technologies, like system-on-a-chip, have initiated limits of data acquisition as they let real-time accurate data acquisition that can be relayed instantly to handheld equipment, like smartphones. In growing economies, several industries are small and medium-scale, creating huge potential.

MARKET RESTRAINTS

The significant restraints for the growth of the corrosion monitoring market are known to be a lack of sufficient regulatory compulsions in most of the businesses in the Asia Pacific and a lack of awareness in end-use businesses. The absence of legal obligation can be attributed to insufficient knowledge among the stakeholders. Moreover, low political willingness or ignorance by government authorities, especially when formulating policies and guidelines, also plays a part in restricting market growth. This inactiveness of public establishments further encourages the market to continue their operations in the same old manner, creating an unfit working environment. Further, such a free hand to companies affects their finances and economics, resulting in poor efficiency and financial instability in the long run.

- According to the report by the NACE International Institute, the direct cost of corrosion to the world economy is projected to be more than 2.5 trillion dollars each year. This comprises the expenses for replacement, maintenance, and repairs of corroded equipment and infrastructure.

It is a baseline cost to infrastructure, with direct expenditure from rust being many billions of dollars annually for pipelines, chemical plants, refineries, and similar structures. The direct price to the country’s economy because of corrosion varies from 3 per cent to 5 per cent of its Gross National Product (GNP). Therefore, jointly all these factors significantly impeding the expansion of this market.

MARKET OPPORTUNITIES

In most cases, they cannot completely incorporate corrosion monitoring systems with sensor equipment for making and other business activities. This is due to the capital fund needed for the procurement of corrosion monitoring systems being more. In past years, with the escalating presence of online corrosion monitoring systems together with some reduction in the price of such monitoring works, there has been a high rise in the penetration of surveillance equipment for quality assurance.

- As per a recent study, given the substantially elevated annual corrosion rate, it is projected that metal loss will reach 100 per cent in around 4 to 5 years.

The rising digital technologies of artificial intelligence (AI) and the Internet of Things (IoT) in the coming years will present potential opportunities, which are at a nascent stage, for the expansion of the corrosion monitoring market. These advances are set to revolutionise the standard methods and techniques for managing rust and shift to modern predictive systems. The combination of AI and IoT provides major prospects for achieving continuous and intelligent surveillance of corrosion processes across their facilities. This enables industrial firms to implement preventative actions even before any signs of physical asset degradation take place, ultimately benefiting the market in the coming years.

MARKET CHALLENGES

The high price of repair and replacement is a major significant restraint that is hindering the corrosion monitoring market expansion worldwide.

- As per recent research, it is calculated that corrosion costs around 279 billion dollars every year to deal with rust and replace or repair the corroded parts or elements. This research further indicates that the expenditure of corrosion could be lowered by 25 per cent to 30 per cent just by deploying renowned rust control measures.

This can be due to various factors impacting the rate of corroding. As a final consumer, a few of those reasons are mostly outside the control of organisations, like the input material utilised to make the machine, the part shapes, and the pressures endured. Apart from these, other factors derailing the market growth trajectory can be internal to the work, for example, the job location environment. As a result, the cost of repair and replacements escalates and the whole burden falls on the shoulders of end user, considerably challenging the market expansion.

The emission of carbon dioxide is another challenge companies and establishments are facing in this market. It possesses a big impact on CO2 discharge worldwide.

- According to a study in the Nature Journal of Science, two researchers from Ohio State University (Columbus, Ohio, USA) identified the carbon dioxide (CO2) emissions linked to the steelmaking process necessary for replacing corroded steel. It discovered that CO2 discharge associated with replacing rusty steel could account for 4.1 per cent to 9.1 per cent of overall CO2 emissions by 2030. In reaching their conclusions, they factored in greenhouse gas reduction targets set by the United States and the European Union.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

11.2% |

|

Segments Covered |

By Type, Technique, End-use, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa. |

|

Market Leaders Profiled |

Permasense Emerson (US), Alabama Specialty Products (US), SGS SA (Switzerland), Aquarius Technologies (India), Cosasco (US), Circle-Aire (Canada), Corrpro Companies Inc (US), Honeywell (US), GE Rightrax (US), ClampOn (Norway), Sensorlink AS (Norway), BAC Corrosion Control (UK), Applied Corrosion Monitoring (UK), ICORR Technologies (US), and Others. |

SEGMENTAL ANALYSIS

Corrosion Monitoring Market By Type

The non-intrusive type holds a significant share of the corrosion monitoring market. Non-intrusive corrosion monitoring is generally referred to as observing the changes in pipes and pipelines. In addition, the segment’s market share is expanding owing to the adoption of online non-intrusive rust surveillance which is rapidly emerging as a best practice in the refining industry. It is facilitated by data-to-desk tracking systems that offer a level of quality and frequency in online wall thickness measurements that were previously unattainable. Preventing rust when a non-stable metal is exposed to water. The protection of these metals is a challenging thing for companies where the non-intrusive type of corrosion monitoring plays an effective role in preventing huge damage. The advanced technology is adding fuel to the growth rate of the market. The use of sensors and ultrasound technology in detecting the corrosion effects enhances the ability to find out the accuracy of promoting the preventive measures that greatly influence the market value.

The intrusive segment is likely to have a prominent growth rate during the forecast period. Moreover, the necessity of implementing these surveillance solutions is growing due to the ageing infrastructure and assets found in facilities like power plants and oil and gas infrastructure. These solutions are becoming increasingly popular worldwide because they can identify severe and rapidly advancing rust that might be overlooked during the periodic inspections. This is expected to increase the segment’s market size in the coming years.

Corrosion Monitoring Market By Technique

By technique, the corrosion coupons segment is ruling with the largest market size, whereas ultrasonic thickness measurement is likely to have great growth opportunities throughout the forecast period. Corrosion coupons help in effectively monitoring the pipeline, which is crucial for safe operation and management. Growing investments in the end-user industries by both public and private organizations are driving the growth rate of this segment. The rising demand to increase the effectiveness of adopting new technologies in order to raise the lifetime of the units is greatly influencing the market value towards a positive one. Ultrasonic thickness measurement is widely adopted by many companies due to its effectiveness in giving precise results to take necessary measures to prevent corrosion at the initial stage. The launch of innovative products with the latest technology by the key companies shall widely enhance the growth rate of the market in the future. The launch of smart corrosion coupons is gearing up to play an important role in oil and gas companies to ensure the structural integrity of the oil and gas pipelines online.

Corrosion Monitoring Market Analysis By End-use

The oil & gas end use segment is leading with a significant share of the corrosion monitoring market. The rising number of oil and gas industries equipped with the most advanced technologies especially in developed and emerging countries like the US, Canada, India, Japan, and China is anticipated to leverage the growth opportunities for the rust tracking industry. Monitoring of corrosion has major applications in end user industries. Early detection and prevention of the rust can reduce the risk of environmental pollution and huge damage.

Chemical segment is next in holding the prominent share of the market.

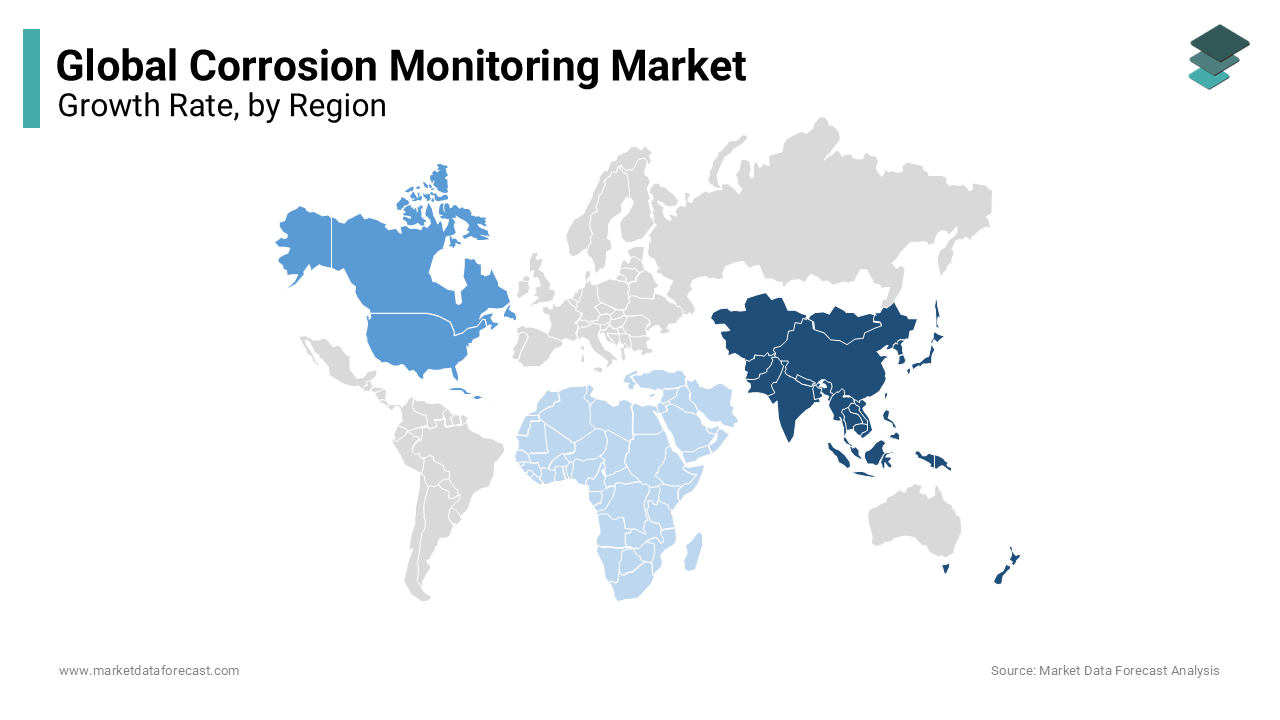

REGIONAL ANALYSIS

Asia Pacific region had the largest market volume value in 2023 and is expected to lead the global market for corrosion monitoring in the forecast period. The regional advantages received by companies in this region, such as cheap labor, ease of availability of raw materials, and promising future opportunities, make the Asia Pacific region have such a high CAGR. Also, due to the rapid growth in the economy and heavy investments across various industries such as chemicals, power generation, and petrochemicals, the growth will strengthen the market in this region.

North America is next in the lead in the global corrosion monitoring market with a similar but slightly lower growth rate when compared to the Asia Pacific. The well-established companies in this region are the major reason for its survival in the market.

Europe, being a stable region for many markets, has a decent market value as of 2018. The growth rate in this region is anticipated to grow gradually by the end of the forecast period.

The Middle East & Africa, and Latin American Regions are the slowest growing in the world because these regions contain countries with low GDP, which on the whole reduces the CAGR of the region, although there are high growth regions of the Middle East.

KEY PLAYERS IN THE GLOBAL CORROSION MONITORING MARKET

Companies playing a prominent role in the global corrosion monitoring market include Permasense Emerson (US), Alabama Specialty Products (US), SGS SA (Switzerland), Aquarius Technologies (India), Cosasco (US), Circle-Aire (Canada), Corrpro Companies Inc (US), Honeywell (US), GE Rightrax (US), ClampOn (Norway), Sensorlink AS (Norway), BAC Corrosion Control (UK), Applied Corrosion Monitoring (UK), ICORR Technologies (US), and Others.

RECENT HAPPENINGS IN THE MARKET

- In February 2024, GPT Industries, a prominent leader in Cathodic Protection Solutions for more than 35 years, revealed the introduction of its remote pipeline monitoring system, Iso-Smart. With nearly four decades dedicated to combating corrosion, GPT utilizes its vast industry knowledge to establish a new benchmark for a flexible and user-friendly remote asset integrity monitoring system. Moreover, it utilizes True RMS technology for accurate data collection. Iso-Smart is a comprehensive solution designed with input from customers to monitor various aspects of Cathodic Protection.

- In July 2024, CorrosionRADAR, a startup based in the UK that specializes in innovative corrosion monitoring technologies, successfully secured 5 million pounds in funding. This investment will allow the Cambridge-based firm to expedite the global rollout of its monitoring systems and continue creating new products aimed at enhancing safety and operational efficiency in the petrochemical, gas, and oil sectors, along with the growing hydrogen industry. Rust poses significant challenges across various industries, with estimates suggesting it accounts for approximately 3 per cent of the world’s GDP annually.

DETAILED SEGMENTATION OF THE CORROSION MONITORING MARKET INCLUDED IN THIS REPORT

This research report on the global corrosion monitoring market has been segmented and sub-segmented based on type, technique, end-use and region.

By Type

- Intrusive

- Non-Intrusive

By Technique

- Corrosion Coupons

- Electrical Resistance

- Linear Polarization Resistance

- Galvanic

- Ultrasonic Thickness Measurement

By End-use

- Oil & Gas

- Chemical

- Manufacturing

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]