Global Composite Cylinder Market Research Report - Segmentation By Fiber Type (Natural fiber composites, Glass fiber composites, and Carbon fiber composites), By Tank Type (Type II, Type III and Type IV), By End User (Wind Energy, Transportation, Aerospace and Defense), and Region - Industry Forecast of 2024 to 2032.

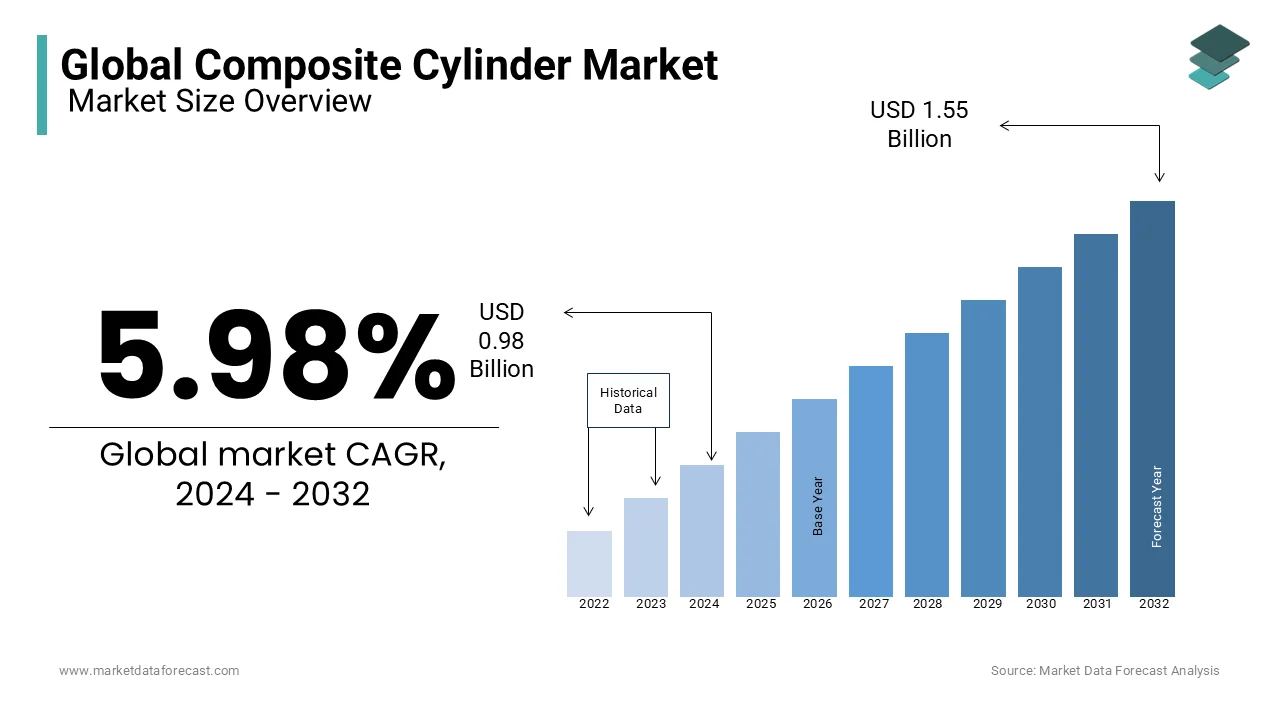

Global Composite Cylinder Market Size (2024 to 2032):

The Global Composite Cylinder Market was valued at US$ 0.92 billion in 2023 and is anticipated to reach US$ 1.55 billion by 2032 from US$ 0.98 billion in 2024 and grow with a CAGR of 5.98% during the forecast period 2024-2032.

MARKET SCENARIO

Composite cylinders, which are UV-protected, lightweight, non-corrosive, and explosion-proof, can be used in place of steel cylinders. As a result of their little weight, transporting these cylinders has become more accessible. This, in turn, results in the reduction of transportation expenses. Furthermore, these composite cylinders are also stain-resistant and translucent, allowing the user to see how much gas is inside. Therefore, because of increased urbanization and disposable affluence, the need for resources has increased, and the demand for composite cylinders in marketing has also increased. Furthermore, the emergence of composite cylinders in emerging countries is due to increased demand for LPG cylinders.

Furthermore, because the production of a composite cylinder is a complicated and high-tech technique, the cost of a composite cylinder is substantially higher than that of a metal one. Because of its properties like strength, temperature, flexibility, heat, and moisture resistance, as well as other properties like durability, stability, and low weight, the Glass fiber variety of composite cylinder is used in building, wind energy, pipes, and tanks, marine, and transportation industries. As a result, it's used in underbody systems, engine covers, deck lids, front-end modules, instrument panels, air ducts, and bumper beams in the vehicle industry.

MARKET DRIVERS AND RESTRAINTS

The composite cylinder market growth is primarily due to increased demand for lightweight storage solutions and an increase in the number of natural gas-powered vehicles.

The cylinders are made of composite polymer and are enclosed in a plastic casing. Composite cylinders are constructed in such a way that they can function in a variety of weather situations. The increased need for composite cylinders in industries such as aerospace and defense, automotive, infrastructure, and wind energy will drive the market. In addition to several government programs encouraging the usage of composite cylinders, the composite cylinder Market is predicted to grow further globally. Carbon fibers, glass fibers, high-density polyethylene, and other outer casing materials are employed in the global Composites Cylinder Market. High-density polyethylene had the greatest penetration in exterior casing materials in 2020, and it is predicted to continue to be the most popular shortly. The lightweight and superior performance property, which contributes to the expansion of high-density polyethylene, is the cause for its greater penetration. The expansion in the Composites Cylinder Market is primarily due to increased urbanization and rising per capita income. The commercial environment will also accept and enhance the use of composite cylinders due to their ease of handling and explosion-bearing capacity. One of the advantages of composite cylinders is that the body structure is translucent, allowing the user to view the gas volume. The composite cylinder is made out of modern polymeric and composite materials that improve the product's quality, design, and safety. LPG cylinders are made of resin and helically woven fiber. This characteristic facilitates the transfer to a new generation of technology while also ensuring that the material is recyclable and UV resistant.

In addition, increased demand from the wind energy, aerospace & defense, and automotive industries is expected to boost the composites industry. Although the most common application of LPG is in the kitchen as composite LPG cylinders, other applications of composite cylinders include autos, where the demand for Type IV composite cylinders is increasing. In addition, the composite cylinder was utilized as a fuel alternative in the railway for the first time in 2019.

Moreover, the strict government rules and high costs are the major factors that limit the global composite cylinder market in the next six years.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

5.98% |

|

Segments Covered |

By Fiber Type, Tank Type, End-User, and Region. |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

Owens Corning, Toray Industries, Inc., Teijin Limited, Mitsubishi Chemical Holdings Corporation, Hexcel Corporation, SGL Group, Nippon Electrical Glass Co. Ltd., Koninklijke Ten Cate BV., Huntsman International LLC., Solvay and Others. and Others. |

SEGMENTAL ANALYSIS

Global Composite Cylinder Market Analysis By Fiber Type

Based on fiber type, glass fiber composites are anticipated to dominate the global Composite Cylinder Market growth during the forecast period. Glass Fiber Composites have been manufactured using various techniques. Therefore, they are widely employed in various applications. Glass fibers have great qualities such as strong strength, flexibility, stiffness, and chemical resistance.

Global Composite Cylinder Market Analysis By Tank Type

Based on tank type, Type IV is the most popular cylinder type in the global composite cylinder market. During the forecast period, the cylinder type is expected to stay larger and faster-growing. Only type IV tanks are represented by all of the major composite LPG cylinder manufacturers. Compared to type I and type III cylinders, type IV cylinders have the most weight reduction and burst pressure.

On the other hand, type III tank-type tends to have the highest value in the global Composite Cylinder Market during the forecast period. This is because Type III gas cylinders have thin and lightweight aluminum liners and are fully overwrapped with carbon composite, reducing weight over Type II cylinders. Therefore, they are the most valuable section.

Global Composite Cylinder Market Analysis By End User

The transportation sector dominates the global Composite Cylinder Market. It is expected to be the largest end-use industry in terms of value, gas carrier, and storage volume within the end-use industry. Due to the lack of sufficient gas pipeline infrastructure and increased demand for bulk transportation, this category is also predicted to develop the fastest among end-user industries. The lack of enough gas pipeline infrastructure in developing countries is the reason behind this.

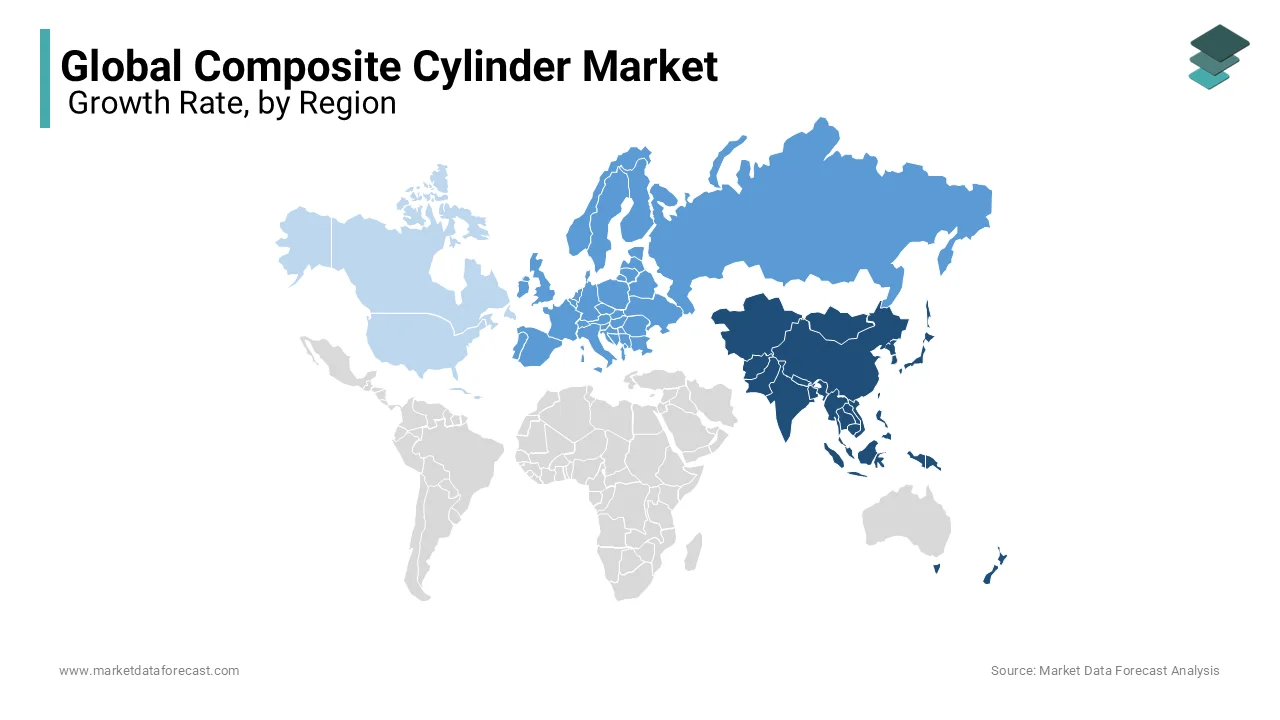

REGIONAL ANALYSIS

Based on value and volume, Asia Pacific is the largest region. The strong growth in the building, transportation, and electrical and electronics segments is the main reason for this increase in the region. In addition, infrastructure expansion increased automotive production, and rapid construction growth is some of the key growth drivers.

Over the projected period, the European Composite Cylinder Market is expected to grow. The rise of the aerospace defense, and wind energy industries will fuel regional demand. Furthermore, regional aerospace firms are increasing their manufacturing capacity to accommodate the growing demand for commercial and military aircraft.

North America is also likely to develop at the fastest rate over the forecast period, primarily owing to the increased manufacturing of alternative fuel vehicles and increased usage of mobile pipelines for gas delivery.

KEY PLAYERS IN THE GLOBAL COMPOSITE CYLINDER MARKET

Companies playing a prominent role in the global composite cylinder market include Owens Corning, Toray Industries, Inc., Teijin Limited, Mitsubishi Chemical Holdings Corporation, Hexcel Corporation, SGL Group, Nippon Electrical Glass Co. Ltd., Koninklijke Ten Cate BV., Huntsman International LLC., Solvay and Others. and Others.

RECENT HAPPENINGS IN THE GLOBAL COMPOSITE CYLINDER MARKET

- On May 19th, 2021, Toray Industries, Inc. announced the development of a high thermal conductivity technology that elevates the heat-dissipating capabilities of carbon-fibre-reinforced plastic (CFRP) to those of metals. With the use of this technology, it disappears heat from its sources through thermal conduction channels within the material. This aids in reducing battery degradation in mobility applications while also improving performance in electronic device applications.

- On January 21st, 2021, Mitsubishi Chemical Corporation announced that it would acquire c-m-p GmbH as a German Carbon Fiber Prepreg Manufacturer through its subsidiary, Mitsubishi Chemical Advanced Material, to strengthen its occurrence in the carbon fiber composite material industry. The deal will be completed in February 2020.

DETAILED SEGMENTATION OF THE GLOBAL COMPOSITE CYLINDER MARKET INCLUDED IN THIS REPORT

This research report on the global composite cylinder market has been segmented and sub-segmented based on fiber type, tank type, end user, and region.

By Fiber Type

- Natural fiber composites

- Glass fiber composites

- Carbon fiber comp

By Tank Type

- Type II

- Type III

- Type IV

By End User

- Wind Energy

- Transportation

- Aerospace

- Defense

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Frequently Asked Questions

What are the main factors driving demand in the composite cylinder market globally?

The demand for composite cylinders is primarily driven by the need for lightweight, durable, and corrosion-resistant cylinders, which are ideal for LPG storage, industrial gases, and medical applications. Additionally, the increasing focus on safety standards, eco-friendliness, and the growth of the oil and gas industry also play significant roles in boosting market demand.

What are the primary applications of composite cylinders?

Composite cylinders are widely used for applications including household LPG storage, industrial gases, medical oxygen, fire extinguishers, and recreational scuba diving. Their durability, lightweight properties, and resistance to rust make them ideal for both residential and industrial applications.

How are advancements in technology impacting the composite cylinder market?

Technological advancements, such as improved polymer resins and fiber-reinforced materials, have enhanced the durability, safety, and performance of composite cylinders. These innovations have made composite cylinders lighter, stronger, and more cost-effective, helping to expand their adoption across various sectors globally.

What is the future outlook for the composite cylinder market globally?

The future of the composite cylinder market looks promising, with expected growth in sectors such as residential LPG, industrial gases, and medical applications. Increased awareness of safety standards, technological advancements in composite materials, and global shifts towards lightweight, eco-friendly solutions will likely continue to drive market expansion.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]