Global Catenary Maintenance Vehicles Market Size, Share, Trends, & Growth Forecast Report By Type (Single Purpose, Multi-Purpose), Application (Repair, Maintenance, Installation), & Region, Industry Forecast From 2024 to 2033

Global Catenary Maintenance Vehicles Market Size

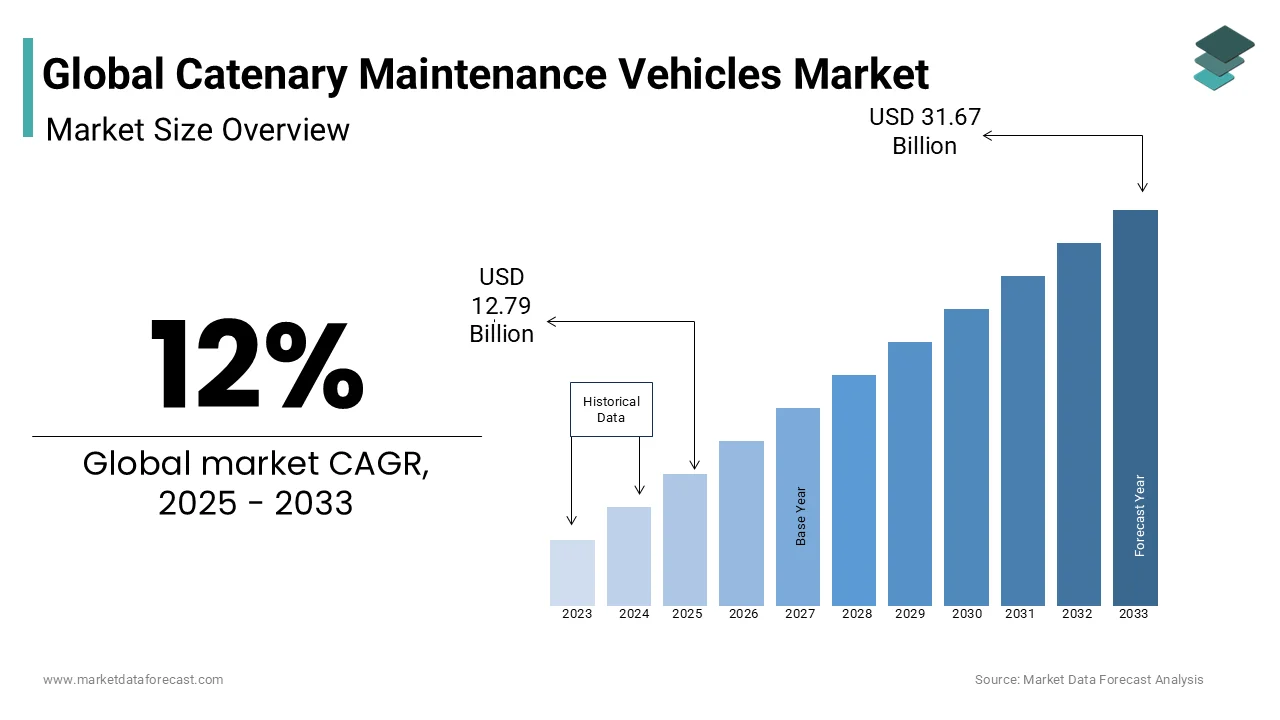

The global catenary maintenance vehicles market was valued at USD 11.42 billion in 2024. The global market is pedicted to reach USD 12.79 billion in 2025 and USD 31.67 billion by 2033, growing at a CAGR of 12% during the forecast period 2025 to 2033.

A catenary maintenance vehicle, also called an overhead line maintenance vehicle, is a specialized vehicle used for maintaining and repairing overhead catenary systems on electrified railways. These catenary systems are the overhead wires that supply electricity to trains running on electrified tracks. Catenary maintenance vehicles are used for tasks related to the upkeep of overhead catenary systems. These tasks include inspection, cleaning, repair, and replacement of components such as wires, insulators, tensioning devices, and support structures, and maintenance of this catenary system is imperative to ensure safe and efficient railway operations. The catenary maintenance vehicles have various key components and features such as a boom and platform; the boom helps in reaching out to the overhead wires, while the platform is a working area where the maintenance personnel perform the tasks of inspection. The other component is the hydraulic system, which allows operators to control the movement of the boom and platform. Along with this, there are equipment storage and inspection tools, such as specialized cameras and sensors, that are mounted on the vehicle for identifying issues. Moreover, the catenary maintenance vehicle also has cleaning mechanisms for clearing the catenary wires from removing dust, dirt, and other contaminants. Overall, catenary maintenance vehicles play a pivotal role in electrified railway systems. They help to improve efficiency, reduce downtime, improve safety, and extend the lifespan of the catenary system; therefore, by addressing issues quickly and efficiently, these vehicles help to keep the railway system running smoothly and reliably.

MARKET DRIVERS

One of the significant factors causing the surge in global demand for electric vehicles (EVs) is the shift towards sustainable and eco-friendly transportation solutions.

This escalating demand is predominantly propelled by a decline in fossil fuel reserves. The demand for electric vehicles has increased, leading to the adoption of electrified railways. The increase in the demand for electric vehicles is propelling the demand for catenary maintenance vehicles as these vehicles help in the optimization of the catenary system, ensuring that the power supply remains consistent and dependable. As the EV evolves, the importance of maintaining this infrastructure becomes pivotal to sustaining the momentum of the electric vehicle demand. Thus, the rise in demand for electric vehicles has led to an increase in the catenary maintenance vehicles market share.

Moreover, the rising investments in railway infrastructure are a major driver of the catenary maintenance vehicles market. Governments and private players are investing heavily in railway infrastructure to improve the efficiency and capacity of the rail network. This includes the construction of new lines, the upgrading of existing lines, and the installation of new technologies. One such technology that is being increasingly adopted by railway infrastructure is the catenary system. The catenary system is a network of overhead wires that transmit electricity to electric trains. This system is more efficient and reliable than other methods. Thus, the installation of new catenary systems is creating a demand for catenary maintenance vehicles. As this catenary maintenance, vehicles are used to inspect, repair, and replace the catenary system. These vehicles are incorporated with a variety of tools and equipment, such as welding machines, wire cutters, and insulator testers. Hence, the increasing funding and investments by the government and railways led to the increase in the adoption of electrified trains and caused an exponential rise in the demand for catenary maintenance vehicles, which is fuelling the catenary maintenance vehicles market demand.

Along with this, increasing urbanization is another important driving factor, leading to an increase in the demand for public transportation, such as metro and light rail systems. These systems are often powered by catenary systems, which are networks of overhead wires that transmit electricity to the vehicles. Therefore, the increasing demand for public transportation is creating a demand for catenary maintenance vehicles as they are used for inspecting, repairing, and replacing the catenary system. The increasing demand for metro and light rail systems is leading to the exponential rise in the catenary maintenance vehicles market size.

MARKET RESTRAINTS

One of the major factors restraining the catenary maintenance vehicles market growth was the high cost involved in purchasing a catenary maintenance vehicle, which is a major investment for railway operators. The cost of purchasing a catenary maintenance vehicle can range from a few million to tens of millions of dollars. This is a significant investment for many railway operators, and this limits the market growth of catenary maintenance vehicles. In addition, the cost of maintaining a catenary maintenance vehicle is also high. This is due to the need for specialized personnel and equipment to operate and maintain these vehicles. Also, the specialized personnel need to have the necessary skills and training to operate the vehicles safely and effectively. The specialized equipment is also expensive, and it needs to be regularly maintained. This further creates a restraint in the catenary maintenance vehicles market. Moreover, these Catenary maintenance vehicles are technically complex machines. This can make them difficult to operate and maintain. The technical complexity of catenary maintenance vehicles can also make it difficult to train new operators. This can lead to delays in maintenance operations and increase costs. Overall, the high initial investment, high operating costs, and technical complexity of catenary maintenance vehicles are major restraints on the catenary maintenance vehicles market share.

MARKET OPPORTUNITIES

The ongoing technological advancements are creating opportunities for the catenary maintenance vehicles market by ensuring higher efficiency, enhanced safety, and improved ease of operation.

These innovations are driven by a combination of automation, data integration, and materials science. Automation reduces human error and increases overall efficiency. Integration of sensors and cameras offers real-time monitoring and diagnostics, allowing for maintenance and quicker issue resolution. As safety has become imperative in railway operations, catenary maintenance vehicles ensure a high level of safety and also reduce manual interventions; vehicles significantly reduce the risk of accidents during maintenance tasks. Also, governments and regulatory bodies are implementing stringent rules and regulations on railway operators to ensure the safety and reliability of their systems. Catenary maintenance vehicles play a pivotal role in helping operators meet these regulatory requirements. By enabling regular inspections, prompt repairs, and adherence to maintenance, these vehicles assist operators in maintaining compliant and well-functioning catenary systems. Hence, the advancing technology, an increased focus on safety, and mandatory compliance with regulations have created an opportunity for catenary maintenance vehicles market expansion.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 to 2033 |

|

Base Year |

2024 |

|

Forecast Period |

2025 to 2033 |

|

CAGR |

12% |

|

Segments Covered |

By Type, Application and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

Vossloh AG , STRUKTON, Thales Group, New Sorema Ferroviaria SPA, TMR, ZWIEWEG, Plasser & Theurer, Amec Foster Wheeler PLC, Alstom Transport, Knorr-Bremse AG, Faiveley Transport and Others. |

SEGMENTAL ANALYSIS

By Type Insights

Based on the type, the catenary maintenance vehicles market is divided into single-purpose and multi-purpose. The multi-purpose segment dominated the market and has the highest market share due to its use for a variety of maintenance tasks, such as inspection, maintenance, and repair. These vehicles are more versatile than single-purpose vehicles, and they can be used to improve efficiency and reduce costs. The single-purpose segment has significant market growth rate over the forecasted period because of their specific maintenance task, such as replacing catenary wires or inspecting insulators.

By Application Insights

Based on their application, the catenary maintenance vehicles market is classified into repair, maintenance, and installation. The maintenance segments dominate the market and have the highest market share, as it is routinely used to perform maintenance tasks, such as inspecting and replacing components. These vehicles are also used to keep the catenary system in good working order and to prevent problems from occurring. The repair segment has steady growth and is used for repairing damage caused to the catenary system, such as broken wires or damaged insulators. Whereas the installation segment has a low market share since it is only when new railways are being built or when existing catenary systems are being upgraded.

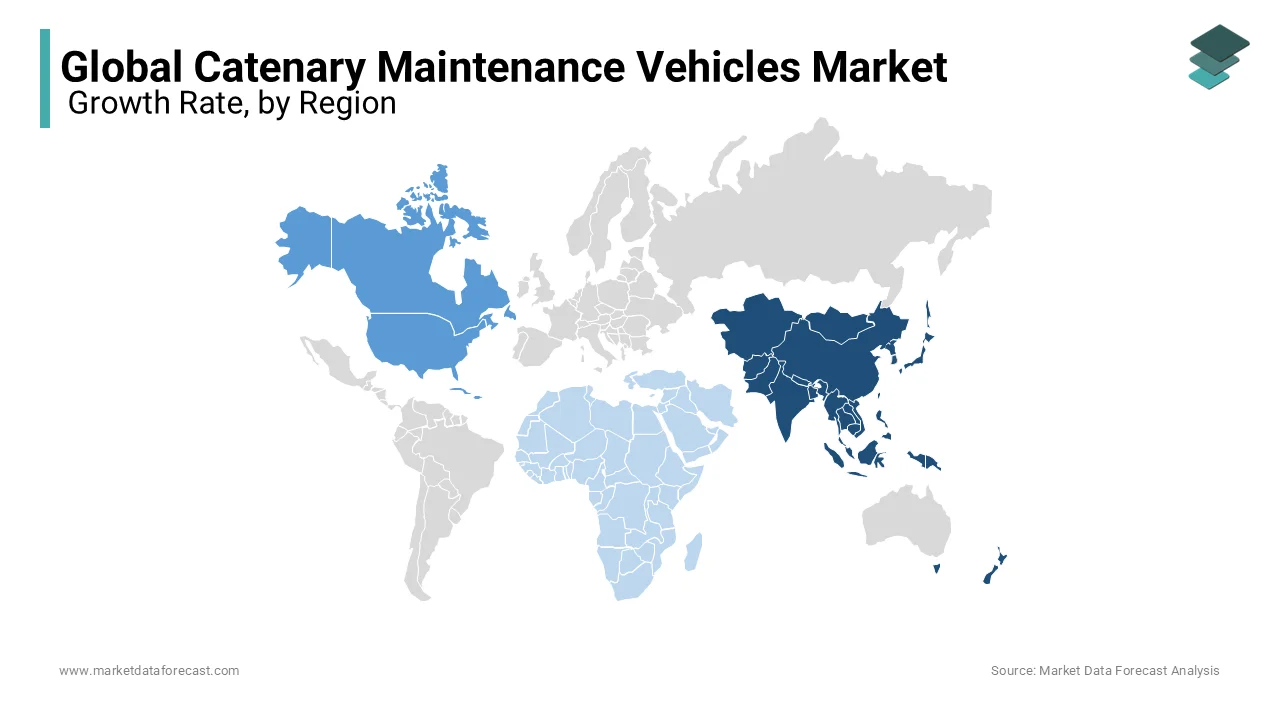

REGIONAL ANALYSIS

Based on the regions, the catenary maintenance vehicles market is classified into North America, Europe, Asia Pacific, Latin America, Middle East, and Africa. The Asia Pacific segment dominated the market shares due to the growing demand for electrified railways in countries such as China, India, and Japan. These countries are investing heavily in new electrified railways, which are driving the demand for catenary maintenance vehicles. North America is second in holding the largest market share due to growing innovation and technological advancement, which is expanding the catenary maintenance vehicles market, as well as government rules and regulations mandating the stringent maintenance of electrified railways. Europe is esteemed to have significant market growth rate in the forecasted period because of environmental and sustainability awareness, which is causing the demand for electrified railways. Latin America has had steady market growth since, due to the growing economy, the government is taking initiatives to develop electrified railways. The Middle East and Africa have low market share as compared to other regions.

KEY MARKET PLAYERS

The major key players in the Global Catenary Maintenance Vehicles Market are Vossloh AG, STRUKTON, Thales Group, New Sorema Ferroviaria SPA, TMR, ZWIEWEG, Plasser & Theurer, Amec Foster Wheeler PLC, Alstom Transport, Knorr-Bremse AG, and Faiveley Transport.

RECENT HAPPENINGS IN THE MARKET

- In June 2023, the Austrian Federal Railways ordered the initial unit from the batch of 56 electric-battery modular maintenance vehicles, which were commissioned by, has been revealed at the Plasser & Theurer manufacturing facility situated in Linz.

- In September 2023, Harsco Rail, a rail manufacturer based in the United States, entered a seven-year contract with infrastructure manager DB Netz. The agreement involves the supply of catenary maintenance vehicles totaling €250 million ($276 million), with a quantity of up to 56 units.

MARKET SEGMENTATION

This research report on the global Catenary Maintenance Vehicles Market is segmented and sub-segmented into the follwing categories.

By Type

- Single Purpose

- Multi-Purpose

By Application

- Repair

- Maintenance

- Installation

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Frequently Asked Questions

What is the major driving factor for the catenary maintenance vehicles market?

Increasing demand for electric vehicles, rising investments in railways infrastructure, and increasing urbanization are major driving factors.

What is the estimated CAGR of the market during the forecast period of 2025–2033?

The market is estimated to register a CAGR of 12% during the forecast period.

Mention the top key players in the catenary maintenance vehicles market?

The major players are TMCP V.V. Vorovsky, G. Zwiehoff, New Sorema Ferroviaria, TESMEC, Aveng Manufacturing, Hilton Kommunal and Socofer

What is the challenging factor for the catenary maintenance vehicles market growth rate?

The high cost involved in the installation and maintenance of catenary maintenance vehicles is one of the major challenging factors for market growth.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]