Global 3D Printing Materials Market Research Report - Segmentation By Material Type (Plastics, Ceramics, Polymer, Metals & Others), By Form (Powder, Filament & Liquid), By Region (North America, Latin America, Europe, Asia Pacific, Middle East & Africa) - Global Industry Analysis on Size, Share, Trends, Growth, Forecast | 2024 to 2032.

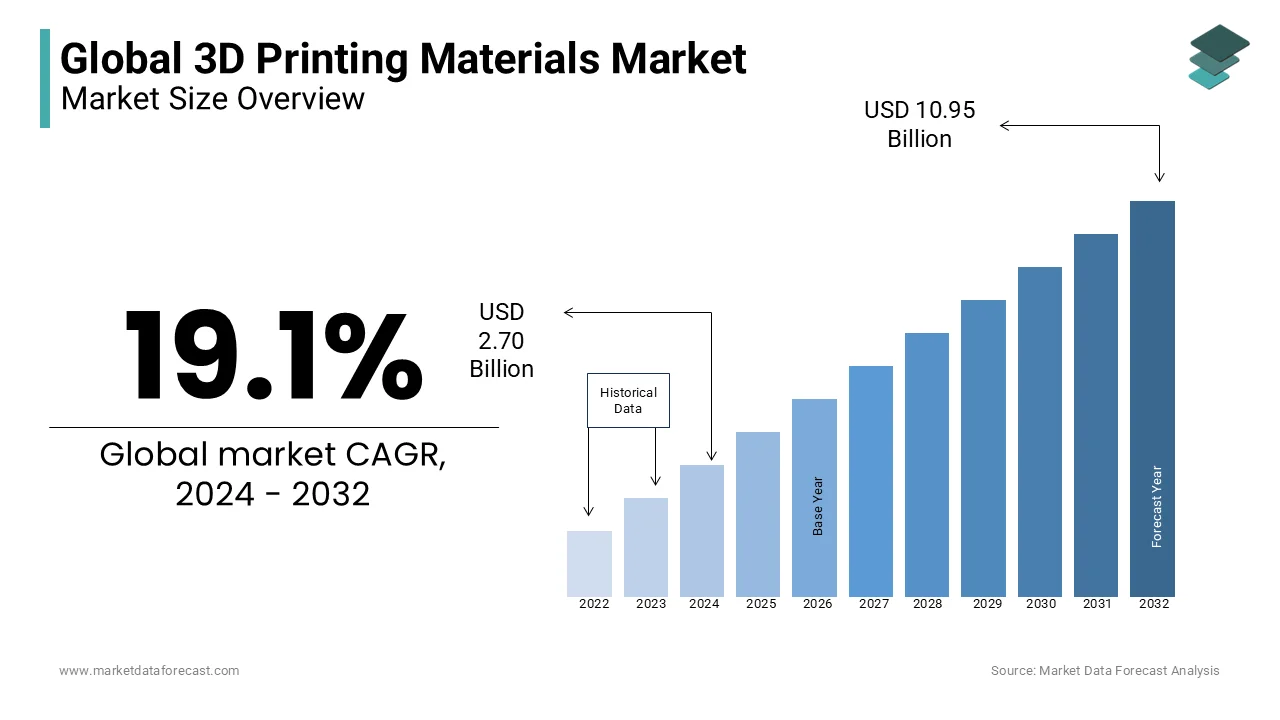

Global 3D Printing Materials Market Size (2024-2032):

The Global 3D Printing Materials Market was worth USD 2.27 billion in 2023 and is anticipated to reach a valuation of USD 10.95 billion by 2032 from USD 2.70 billion in 2024. it is predicted to register a CAGR of 19.1% during the forecast period 2024-2032.

Current Scenario of the 3D Printing Materials Market

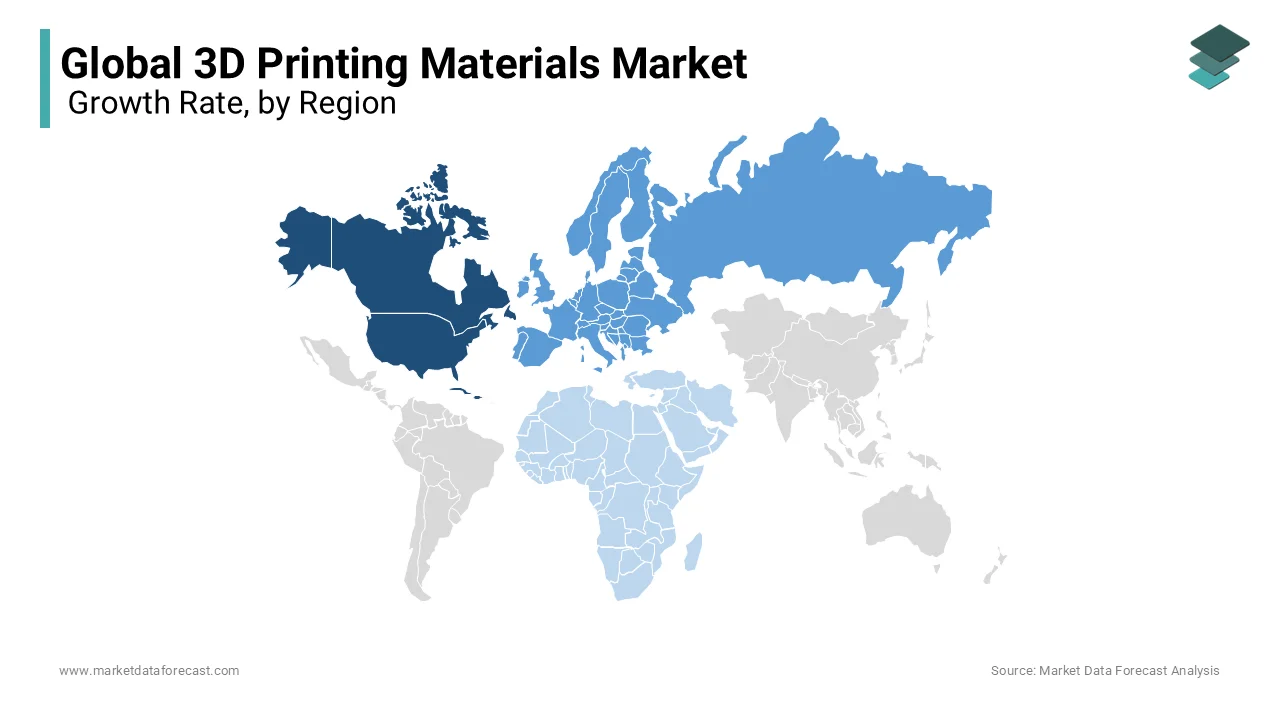

The 3D printing material market is currently dominated by the United States and Europe. Both regions have a high number of patents in this technology, and when combined, the percentage of total IPFs for 3D printing technologies filed globally, i.e., over 50000 since 2001, was a staggering 72.7. Out of these, the US accounts for 39.8 percent, while Europe has 32.9 percent. This shows their domination in the 3D printing industry. And, within Europe, Germany is at the forefront with around 41 percent of the region’s market share and France at the second with 12 percent. Whereas China, South Korea, and Japan fall behind with 3.7 percent, 3.1 percent, and 13.9 percent, respectively. But, in the coming years, the emerging economies in the Asia Pacific, like India, Indonesia, and Vietnam, are presenting immense opportunities in the healthcare, automotive, industrial equipment, etc. sectors, which will ultimately expand the 3D printing material market.

MARKET DRIVERS

The diversification and development of new materials, multi-material and multi-functional printing coupled with enhanced resolution and surface finish are driving the 3D printing materials market.

Smart materials can adjust or alter their behavior or properties in response to ecological factors like pressure, electromagnetic fields, light, and temperature. It can be utilized in additive manufacturing methods such as fused deposition modeling (FDM) and stereolithography (SLA) to make objects with shape memory capabilities. Other factors are multi-material printing, cloud-based printing services, and advancements in robotics that are propelling the growth of 3D printing technology.

Additionally, it provides favourable market conditions for aftermarket applications as producers are progressively using additive manufacturing technology to create new parts for this segment.

MARKET RESTRAINTS

The key hurdles for the 3D printing materials market growth are the lack of adequate professionals, limited funding, expensive raw materials, low adoption rates and inferior quality of final products.

As per a 2023 survey, production companies are struggling to overcome the need for a skilled workforce and the proficiency to incorporate this with the current manufacturing processes, which is limiting the adoption rate. Out of 327 participating producers from the United States, Japan, and Germany, around 59 percent utilize 3D printing, the remaining 31 percent are still thinking about it, and lastly, 9 percent are totally against their application.

MARKET OPPORTUNITIES

The 3D printing materials can significantly contribute to environmental sustainability. Several governments, international agencies, and bodies worldwide have marked this as their topmost priority in the last few years and are actively exploring eco-friendly solutions. Additive manufacturing helps lower waste by utilising multiple layers of special inks produced from resin and other materials. On the contrary, other manufacturers remove several parts to build an object, which in turn increases waste management difficulties.

Apart from this, Asia Pacific is witnessing significant growth in the manufacturing of consumer electronics, automobiles, and defense sectors. Also, India surpassed Japan, Australia, Hong Kong, and Singapore (excluding China) to lead the data center capacity hub. This will help in building and delivering customised components with a short lead time.

MARKET CHALLENGES

The cost of pre and post-processing, limited material selection and technology constraints are decreasing the 3D printing materials expansion rate. All three challenges are highly common in consumer electronics, healthcare, heavy equipment, automotive, industrial machines, and plastics & packaging industries. Other factors include the absence of in-house expertise and the cost of system equipment. The study states that close to 54 percent consider material availability and cost as the key problem. Also, 43 percent say manpower issues, such as the lack of subject matter experts and the lack of qualified people, are the main challenges.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

19.1% |

|

Segments Covered |

By Material Type, Form, and Region |

|

Various Analyses Covered |

Global, Regional and Country Level Analysis; Segment-Level Analysis; DROC; PESTLE Analysis; Porter’s Five Forces Analysis; Competitive Landscape; Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

3D Systems Corporation (U.S.), HP INC. (U.S.), Proto Labs, Ltd. (U.S.), Hoganas AB (Sweden), Royal DSM N.V. (Netherlands), Lithoz GmbH (Austria), The ExOne Company (U.S.), Markforged, Inc. (U.S.), Sculpteo (France), EnvisionTEC, Inc. (U.S.), and Others. |

SEGMENTAL ANALYSIS

Global 3D Printing Materials Market Analysis By Material Type

The plastics segment accounts for the biggest portion of this category of the 3D printing materials market. The consumption of these plastics has surged over the past few years in terms of making prototypes. A large number of producers are believed to use this method to achieve higher production quantities. Besides this, 3D printing plastics have built various noticeable transformations in the automobile manufacturing sector.

Global 3D Printing Materials Market Analysis By Form

The powder segment is the dominant category of the 3D printing materials market and is estimated to expand during the forecast period. This is due to its increased use in the aerospace, defence, and automotive industries. Powder enables the production of complex geometries and enhances mechanical qualities, which helps in meeting stringent industry requirements. Moreover, the development of a wide variety of materials with improved automatic qualities is influencing the demand and the segment’s market growth rate.

Global 3D Printing Materials Market Analysis By End-user Industry

The aerospace and defence segment is expected to drive up the growth rate of the 3D printing materials market due to the rising application of nickel, aluminium, titanium and stainless steel. In the aerospace sector, titanium is preferred because of its high resistance, lightweight, and other advantages. It poses a vast potential for 3D-printed titanium items to propel this industry as it provides a great strength-to-weight ratio and low thermal conductivity. Likewise, recently, in May 2024, the Indian Space Research Organisation successfully conducted the test of the PS4 liquid rocket engine, which was manufactured using this production technology. Hence, both defence and aerospace can unlock new possibilities in 3D metal printing.

REGIONAL ANALYSIS

North America is the biggest contributor in terms of new developments and applications and holds a large portion of the 3D printing materials market share. Like recently, in April 2024, the University of Florida successfully invented vapour-induced phase-separation 3D printing or VIPS-3DP. It is a procedure to build multi and single-material articles. Moreover, the region uses this to produce products and components for cars, athletic shoes, and even NASA rocket engines. Hence, we can say that 3D printing is now at the center of US manufacturing and expanding its technological edge from traditional to advanced ones.

Europe is a main focus area for 3D printing technology and is believed to thrive further in the forecast period. This is due to the rising necessity of strong, affordable, and high-speed prototypes by most small and medium enterprises. Moreover, the penetration rate of this technology was high in the aeronautics and health industries, which presents potential future growth opportunities. As per the European Patent Office’s data published in September 2023, 3D printing has risen 8 times quicker than the average of all technologies in the last 10 years. It also revealed that the average patent filling under this was more than 26 percent in the region. Interestingly, it holds 4 out of 10 positions for research establishments in additive manufacturing invention.

Asia Pacific is anticipated to witness a significant jump in its share of the 3D printing materials market. It is the fastest-growing industry with rapid adoption of additive manufacturing in advancing and upgrading its production capacities over the region. Moreover, China and Japan are leading the APAC market and are expected to maintain their dominance in the coming years as well. In addition, according to a study, the most prevalent printing material types are plastics (such as polylactic acid), Powders (for example polyamide and aluminide), liquid polymer (named resin), Metals (stainless steel, bronze, nickel and aluminium) and Other materials (graphite, graphene and carbon fibre)

Latin America 3D printing materials market is expected to propel at a moderate pace during the forecast period. Regional growth is pushed forward by Brazil’s progressive adoption and usage of the metal industry. It holds a considerable share because of the growing automotive, defence and aerospace sectors. Another factor driving the LA market is the rising investments and innovations in the healthcare domain. Also, technologies related to polymer manufacturing are more dominant in this continent. However, inadequate government policies and limited access to high-value knowledge to promote robust technological progress are holding it back from making further advancements.

The Middle East and Africa 3D printing materials market is estimated to move forward at a steady pace in the future. The ME countries have experienced an increase in acceptance of additive manufacturing in different industries in the last few years. The main force stimulating growth is the active initiatives of government and private entities. For instance, UAE’s programs for promoting AM adoption, the Dubai 3D Printing Strategy, and the Dubai 3D Printing Strategic Alliance are two major steps taken in this regard. Africa holds immense growth potential as its manufacturing industry requires capacity building and improvements.

KEY PLAYERS IN THE GLOBAL 3D PRINTING MATERIALS MARKET

Companies playing a prominent role in the global 3D printing materials market include 3D Systems Corporation (U.S.), HP INC. (U.S.), Proto Labs, Ltd. (U.S.), Hoganas AB (Sweden), Royal DSM N.V. (Netherlands), Lithoz GmbH (Austria), The ExOne Company (U.S.), Markforged, Inc. (U.S.), Sculpteo (France), EnvisionTEC, Inc. (U.S.), and Others.

RECENT DEVELOPMENTS IN THE GLOBAL 3D PRINTING MATERIALS MARKET

-

In May 2024, a new 3D printing method was invented by Canadian experts to manufacture microlenses with commercial-level optical quality quickly. The new approach with an imaging performance produced a millimetre-sized plano-convex optical lens. It also displayed the ability to make optical elements which are ready to use in just 30 minutes.

-

In April 2024, The Factory of the Future 1.0 (FoF 1.0) 3D printer was launched at the University of Maine. It is considered the world’s largest 3D printer with the capacity to produce items around 96 feet (29m) long. Such big machines can be utilised for manufacturing different sections of houses rather than a complete house and at times can execute parts restoration or decorative components. Also, it is expected to contribute to building affordable housing along with boats, wind turbines, and bridges and can generate up to 227 kg (500lbs) of stuff or matter.

DETAILED SEGMENTATION OF THE GLOBAL 3D PRINTING MATERIALS MARKET INCLUDED IN THIS REPORT

This research report on the global 3D printing materials market has been segmented and sub-segmented based on material type, form, end-user industry, and region.

By Material Type

- Plastics

- Ceramic

- Metals

- Other Materials

By Form

- Powder

- Filament

- Liquid

By End-user Industry

- Automotive

- Medical

- Aerospace and Defense

- Consumer Electronics

- Other End-user Industries

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Frequently Asked Questions

What is the projected size of the global 3D printing materials market by 2029?

The global 3D printing materials market is anticipated to reach approximately USD 10.95 billion by 2032, with a projected compound annual growth rate (CAGR) of 19.1% from 2024 to 2032.

What are the main drivers and restraints impacting the 3D Printing Materials Market?

Drivers include the adoption of 3D printing technology, benefits such as reduced waste and cost-effectiveness, and increased application in industries like automotive and aerospace. Restraints include the high initial cost of equipment and materials, and the requirement for high voltage power sources.

How has COVID-19 impacted the 3D Printing Materials Market and which regions show significant market potential?

COVID-19 led to disruptions in supply chains but also increased opportunities in healthcare. North America and Asia-Pacific exhibit high market potential due to favorable trends in industries like medical and aerospace, as well as government initiatives supporting research and development.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from $ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: [email protected]